Unplasticized Polyvinyl Chloride (uPVC) is growing at a very high speed as the material of preference in construction, plumbing, and material used in industries because of its high durability, resistance to chemicals, and affordability. Knowing the special features and advantages of uPVC can aid you to make wise choices on the next project you will be undertaking, be it residential plumbing, a commercial building, or a project involving an industrial infrastructure.

Understanding Unplasticized Polyvinyl Chloride (uPVC) Pipe

What is uPVC?

Unplasticized Polyvinyl Chloride (uPVC) is a hard type of PVC with no additives that will allow it to be soft or pliable. Unlike normal PVC developed with plasticizing chemicals to make them flexible, uPVC can retain the initial stiff nature, leading to its high strength, durability, and chemical resistance. Whether you're considering an industrial system or exploring the cost of a uPVC 3/4 pipe price or uPVC pipe 6 inch price for your project, the value uPVC delivers in return is unmatched.

Key Chemical Composition:

-

Primary polymer: Polyvinyl chloride resin

-

Stabilizers: Heat and UV stabilizers for longevity

-

Impact modifiers: Enhance toughness and crack resistance

-

Processing aids: Improve manufacturing consistency

-

Pigments: Provide color and UV protection

Unique Properties of UPVC

-

Rigid and Durable: Unplasticized material in UPVC ensures that it is quite tough and resistant to destruction and wear.

-

Non-Toxic: UPVC does not contain Bisphenol A (BPA) and phthalates, which makes it safe when used in potable water systems.

-

Weather-Resistant: UV rays, moisture, and fluctuating temperatures have minimal impact on UPVC.

-

Corrosion-Resistant: It doesn’t rust or corrode, even in chemically aggressive environments.

-

Lightweight: Though tough, the UPVC is lightweight and facile to transport and install, which saves on transportation and installation costs.

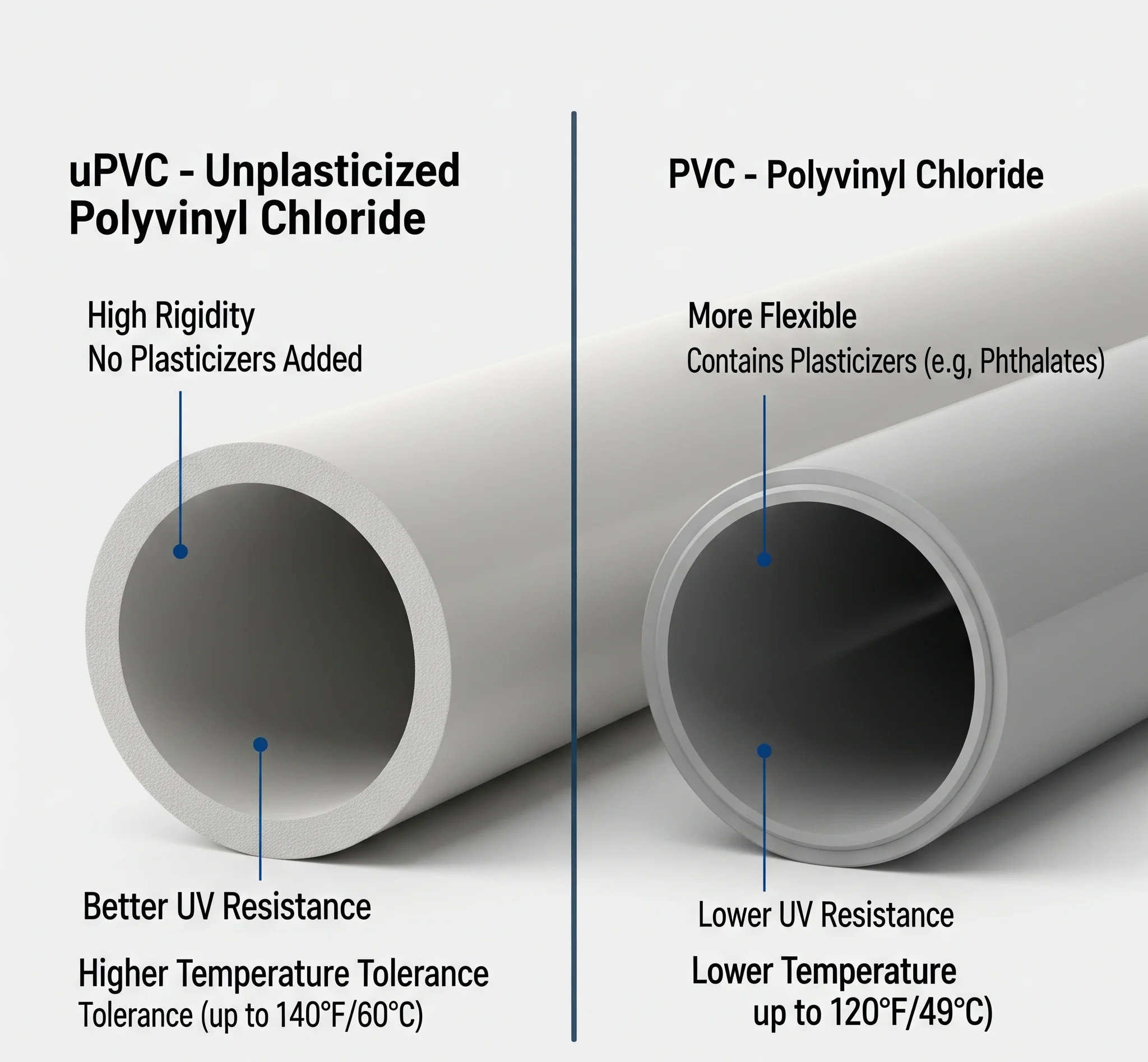

uPVC vs. Regular PVC: Critical Differences

Structural Differences:

-

uPVC: No plasticizers, rigid structure, higher density

-

Regular PVC: Contains plasticizers, flexible, lower density

-

Molecular stability: uPVC offers superior long-term stability

-

Temperature resistance: uPVC handles higher temperatures better

Performance Comparison:

| Property | uPVC | Regular PVC |

|---|---|---|

| Tensile Strength | 50-55 MPa | 20-25 MPa |

| Impact Resistance | Superior | Good |

| Chemical Resistance | Excellent | Good |

| UV Resistance | Excellent | Fair |

| Service Life | 50-100 years | 20-40 years |

| Cost | 15-25% higher | Lower initial cost |

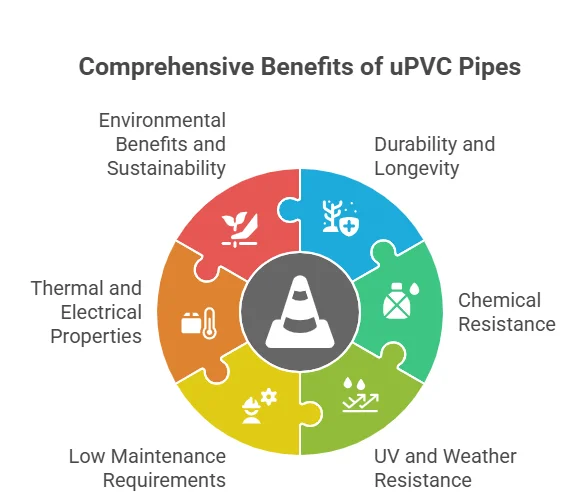

Key Benefits of Unplasticized Polyvinyl Chloride Pipe

1. Exceptional Durability and Longevity

Extended Service Life: uPVC pipes are engineered to deliver a service life of up to 50–100 years under standard operating conditions, making them a smart, long-term investment for infrastructure and utility networks. This exceptional lifespan is due to uPVC’s inherent resistance to environmental degradation, chemical exposure, and mechanical wear.

Impact and Stress Resistance:

-

High tensile strength: 50–55 MPa, significantly higher than conventional PVC pipes (20–25 MPa)

-

Excellent impact resistance: Withstands high mechanical stress without cracking

-

Fatigue resistance: Endures repeated pressure cycles without material failure

-

Dimensional stability: Minimal thermal expansion or contraction, ensuring consistent performance

Weather Resistance: uPVC pipes retain their structural and functional integrity across a wide temperature range, from -40°F to 140°F (-40°C to 60°C). This makes them highly suitable for underground, outdoor, and exposed installations in diverse climatic zones worldwide.

2. Superior Chemical Resistance

Broad Chemical Compatibility: uPVC pipes exhibit excellent resistance to a wide range of chemicals, making them highly reliable in industrial applications where exposure to aggressive substances is common. Their chemical inertness ensures long-lasting performance in challenging environments such as chemical processing, water treatment, and effluent management.

Resistant Chemicals Include:

-

Acids: Hydrochloric, sulfuric, and nitric acids

-

Alkalis: Sodium hydroxide and potassium hydroxide solutions

-

Salts: Most inorganic salt solutions

-

Organic compounds: Many alcohols and hydrocarbons

-

Water treatment chemicals: Chlorine, fluorine, and ozone

Industrial Applications: Thanks to this broad chemical compatibility, uPVC pipes are widely used in chemical processing plants, water treatment facilities, and industrial waste management systems, where resistance to corrosion and chemical attack is critical for safe and sustained operation.

3. Outstanding UV and Weather Resistance

UV Stabilization: The uPVC systems formed today contain superior UV stabilizers, which ensure long-term performance in both color and structural degradation under exposure to sunlight.

Weather Performance Benefits:

-

Color retention: Maintains original appearance for 20+ years

-

No brittleness: Resists becoming brittle from UV exposure

-

Thermal stability: Handles temperature cycling without cracking

-

Moisture resistance: Unaffected by humidity and rain

Outdoor Application Advantages: These characteristics render uPVC suitable for external use in decorating windows and siding, roofing systems, and other external infrastructure where there is an inescapable long-term exposure to the elements. For example, 4 inch uPVC pipe and uPVC pipe fittings are often preferred for external systems requiring robust weatherproofing.

4. Low Maintenance Requirements

Self-Cleaning Properties: uPVC pipes feature a smooth, non-porous texture that resists dirt and soiling, making them easy to clean with just soap and water, no need for special cleansers or treatments.

Maintenance Benefits:

-

No painting required: Color is integral to the material

-

Corrosion resistant: Never rusts or requires protective coatings

-

Easy cleaning: Simple soap and water maintenance

-

No warping: Maintains shape and fit over time

-

Pest-resistant: Unaffected by insects or rodents

Cost Savings: These low-maintenance properties translate into significant long-term cost savings. On average, maintenance costs for uPVC pipes are 70–80% lower compared to traditional materials like wood or metal, making them an economical and practical choice for infrastructure projects.

5. Excellent Thermal and Electrical Properties

Thermal Insulation: uPVC pipes offer excellent thermal insulation, making them suitable for energy-efficient plumbing and HVAC applications.

Thermal Characteristics:

-

Low thermal conductivity: 0.16 W/m·K compared to 50 W/m·K for aluminum

-

Energy efficiency: Reduces heating and cooling costs by 20-30%

-

Thermal expansion: Minimal movement with temperature changes

-

Fire resistance: Self-extinguishing properties enhance safety

Electrical Insulation: Due to their strong insulating properties, uPVC pipes are widely used in electrical conduit systems, effectively preventing electrical leakage and ensuring safety in installations.

6. Environmental Benefits and Sustainability

Eco-Friendly Manufacturing: Modern uPVC pipe production emphasizes sustainability by incorporating recycled materials and energy-efficient processes that reduce environmental impact without compromising quality.

Environmental Advantages:

-

Recyclable: 100% recyclable at end of service life

-

Energy efficient: Reduces building energy consumption

-

No toxic leaching: Safe for potable water applications

-

Reduced waste: Long service life minimizes replacement needs

-

Low carbon footprint: Energy-efficient manufacturing processes

Green Building Certification: uPVC pipes can contribute points toward LEED and other green building certification systems due to their energy-saving, non-toxic, and recyclable nature, making them a preferred choice for sustainable infrastructure.

Primary Applications of uPVC

1. Construction and Building Materials

Window and Door Frames: uPVC window and door frames possess better ratings for insulation, security and durability over traditional materials. They yield good weather tightness, cut energy costs, and need little support over their 30-50-year length of existence.

Roofing and Siding Systems: uPVC roofing tiles and side cladding panels offer long-lasting, weather-tight building envelopes that look great and perform great decade after decade without painting or coating.

Interior Applications:

-

Ceiling panels: Easy installation and maintenance

-

Wall cladding: Moisture-resistant interior surfaces

-

Trim and molding: Precision-manufactured architectural details

-

Flooring systems: Durable, easy-to-clean surfaces

2. Plumbing and Water Systems

Pressure Pipes: uPVC pressure pipes handle water distribution systems with excellent performance characteristics:

-

Pressure ratings: Available in classes from 125 PSI to 400 PSI

-

Corrosion resistance: Unaffected by water chemistry variations

-

Smooth bore: Reduces friction losses and energy costs

-

Joint integrity: Solvent-welded joints provide permanent, leak-free connections

From residential to industrial scale, the use of unplasticized polyvinyl chloride pipe ensures a leak-free, corrosion-resistant system. Whether you're looking at a uPVC pipe 4 inch line or comparing uPVC pipe price options for bulk purchase, the Scotto pipe's performance remains consistent.

-

Drainage Systems: uPVC drainage pipes offer superior performance for waste water management.

-

Chemical resistance: Handles aggressive wastewater without degradation

-

Smooth interior: Prevents buildup and blockages

-

Root resistance: Special formulations prevent root intrusion

-

Long service life: 50-100 year design life for buried applications

3. Industrial Applications

Chemical Processing: uPVC's chemical resistance makes it ideal for industrial chemical processing applications, including:

-

Reactor vessels: Corrosion-resistant process equipment

-

Piping systems: Chemical transfer and distribution

-

Storage tanks: Safe storage of aggressive chemicals

-

Ventilation systems: Fume extraction and air handling

Water Treatment Facilities: uPVC components are essential in water and wastewater treatment.

-

Filter housings: Durable, corrosion-resistant construction

-

Distribution systems: Reliable water delivery networks

-

Chemical feed systems: Safe handling of treatment chemicals

-

Clarifier components: Long-lasting treatment equipment

Installation and Handling Considerations

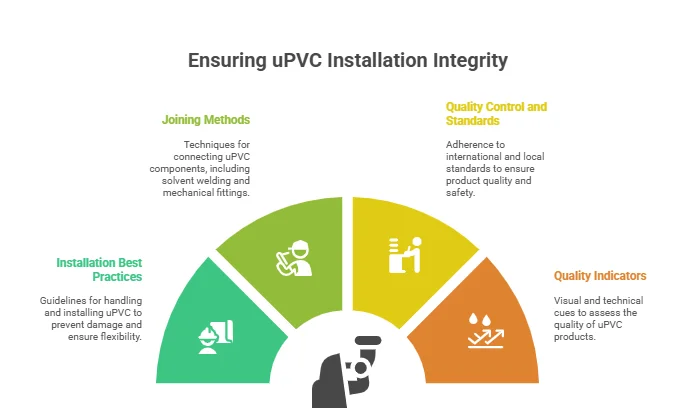

One of the main factors that is critical to the long-term performance and reliability is correct control and installation of uPVC components. This guide provides best-practice, joining techniques, and central quality criteria to be used to achieve safe, compliant and long-lasting installations.

Installation Best Practices

To work with uPVC materials, care must be taken such that they are not cracked or damaged. Install pipes at a high temperature that is above 32 degrees F(0°C) in order to assure material flexibility and avoid brittleness. Have the supports placed within the range of 3 to 4 feet to ensure the alignment of a pipe and minimize stress. In cases of a long run of pipe, include expansion joints to allow expansion and contraction of the pipe. To ensure secure joints, always use clean-cutting, sharp and well-manufactured tools to achieve the best results in terms of precision and burr free cutting.

Joining Methods

In the system, uPVC allows various joining techniques with reference to the application. Solvent welding provides permanent, deep and leak-proof bonds. Mechanical connections are made via mechanical fittings, which are easily disassembled and are not suited to heavy-duty systems that require frequent access and are normally made via flanged connections. Push-fit systems provide an expedient solution with tool-free installation, and they are characterized by particular use cases.

Quality Control and Standards

Quality uPVC products should meet the approved international standards. These are ASTM specifications on the materials and performance, ISO certification on quality assurance and NSF approval to be used in potable water applications. Also, there are local codes to be taken into consideration as a legal requirement.

Quality Indicators

To assess the quality of uPVC products, look for consistent wall thickness for reliable pressure handling, a smooth surface finish indicating controlled manufacturing, and color uniformity which reflects proper formulation. Certified products should also bear clear markings showing compliance, specifications, and manufacturing data.

Scotto Pipes: Leading Manufacturer & Exporter of High-Quality uPVC Solutions

In regard to selecting high-quality, sustainable and standard-compliant uPVC products, Scotto Pipes takes the leadership of the industry. Being a reliable company in the production and export of high-quality uPVC pipes and fittings, Scotto Pipes is determined to assist in providing performance-based products in the construction, plumbing, water management, and industrial infrastructure fields.

Scotto Pipes has given much attention to quality control, innovation, and sustainability. Thus, we make sure that all our products created using the uPVC are as per international certifications like ASTM, ISO, and BIS. You may require pressure-rated plumbing pipes, chemically and wear-resistant industrial lines, or weatherproof uPVC conduits. Scotto Pipes will provide products designed to meet high efficiency, low maintenance and long life requirements, which makes them the preferred products in any modern infrastructure and green building projects anywhere in the world. Whether you need a 4 inch uPVC pipe, a budget-friendly uPVC pipe price, or full uPVC pipe fittings range, Scotto Pipes ensures value and quality.

Conclusion

Unplasticized Polyvinyl Chloride (uPVC) possesses an outstanding balance of durability, chemical resistance and cost, which makes it an ideal building material in the construction, plumbing and industrial fields. The major advantages of uPVC are long service life (50-100 years), excellent chemical and UV resistance, low maintenance needs, good thermal performance and the fact that it is highly eco-friendly.

Although uPVC is expected to be 15-25 percent more expensive to build over standard PVC, the life cycle value profile is quite attractive. Inferior cost in maintenance, enhanced energy use, and extended service lifetime, uPVC is found to give its payback in 5-10 years and keeps on giving after its long life.

The sustainability and energy efficiency attributes of building codes are seeing more and more uPVC applicability as its contribution to green building certification and other environmentally friendly properties increases to be of interest to progressive builders and facility managers. If you are looking to set up residential construction, commercial development, or industrial infrastructure, uPVC material will provide reliable performance, value and meet the needs of modern applications. The successful history of the use of the material in various applications and climates, as well as innovations in formulation and production, make uPVC one of the top material solutions of the future generation of construction and infrastructure projects.