Introduction

One of the issues that industrial facilities that handle chemicals are confronted with is the safe and reliable transfer. With acids, alkalis, solvents, or process water, the correct pipe solutions will make operations run smoothly with minimum chances of leakages, corrosion and contaminations. Selecting the inappropriate piping system may result in downtime and expensive adoptions or even, there may be safety hazards.

In this blog, we will discuss the reasons why specialized pipe solutions are important, the most common materials used and which one best fits various applications of chemicals.

Why Specialized Pipe Solutions Are Needed in Chemical Handling

Chemicals are not just ordinary fluids. They may be very corrosive, reactive and may be toxic. Ordinary industrial piping is likely to wear out prematurely, leak chemicals, and be hazardous to the environment.

This is why industries need such special solutions of pipes that should be resistant to corrosion, high-temperature, and be of high safety standards. It is not only the fluid transfer but long-term reliability and ability to comply with the industry regulations.

Key Materials Used in Industrial Chemical Pipes

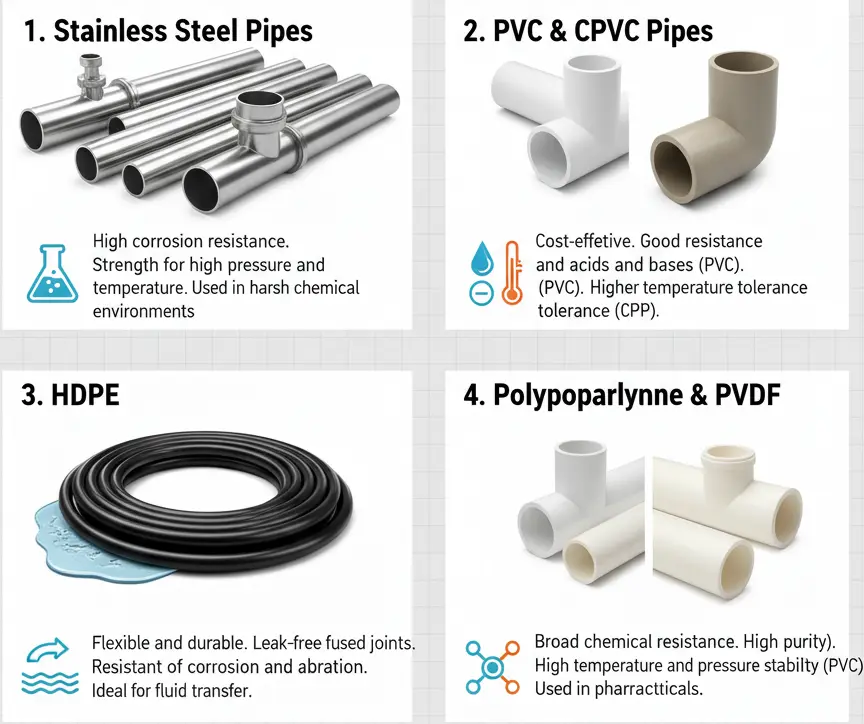

Different applications demand different piping materials. Here are the most common ones:

1. Stainless Steel Pipes

-

Good strength and high pressure resistance.

-

Resists high temperatures.

-

Usually used in refineries, petrochemical plants, and pharmaceutical industries.

2. PVC & CPVC Pipes

-

Portable, simple to set-up and affordable.

-

Insensitive to a vast range of acids, alkalis and salts.

-

CPVC is capable of more heat than regular PVC.

3. HDPE Pipes

-

Flexible and corrosion resistant.

-

Extensive outdoor service life.

-

Applicable in wastewater and chemical transfer.

4. Polypropylene & PVDF Pipes

-

Special-purpose thermoplastics.

-

Very good at working with very aggressive chemicals.

-

PVDF specifically is purse sealant and strong.

Top Pipe Solutions for Industrial Chemical Handling

When selecting a piping system, industries generally choose from the following leading solutions:

1. Stainless Steel Piping Systems

Stainless steel is also one of the best choices in case of heavy-duty chemical handling. It is hard to scale and retains its strength at high temperature, and can be used in pressurized conditions. Nonetheless, it may cost more than plastic ones.

2. PVC & CPVC Piping Solutions

Facilities which deal with medium strength chemicals make use of PVC suction and delivery pipes. CPVC, which has a higher temperature-endurance, is commonly found in hot-chemical lines of transfer. They are inexpensive and can be readily substituted.

3. HDPE Pipe Solutions

High - Density Polyethylene (HDPE) pipes have been the choice when it comes to industries that require long lifespan pipes which are corrosion resistant. They are light, flexible and can be installed with low cost hence they are suitable in the outdoor and underground pipelines.

4. Composite Pipes

Composite pipes are made using a variety of materials in several layers, and they are strong, flexible, and resistant to chemicals. They are commonly applied in high-discipline industries, like oil & gas.

5. Flexible Hose Pipes

Flexible hoses are safe and versatile pipe applications in applications that require movement like mobile tanks or temporary installations. Depending on the application, they can be strengthened to add more strength.

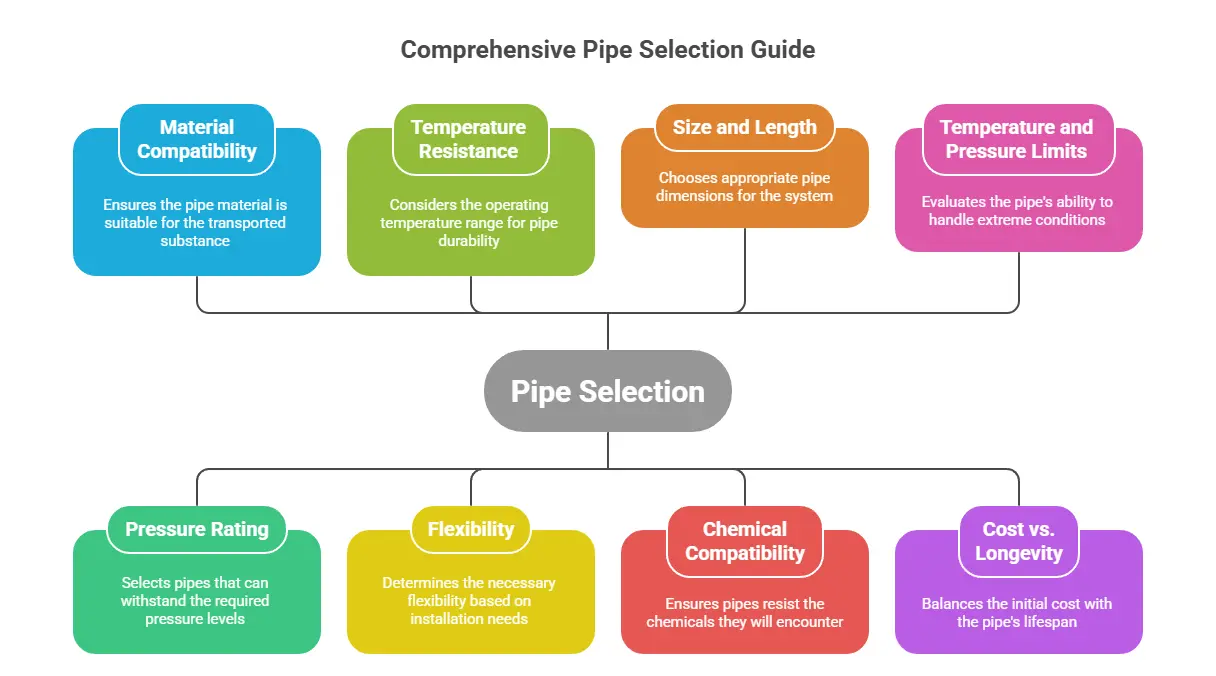

Factors to Consider When Choosing Pipe Solutions

Before finalizing a piping system, industries should evaluate:

-

Material Compatibility: The material used to make the pipe must be in compatibility with the substance transported.

-

Pressure Rating: Select a pipe that is able to resist the level of pressure needed.

-

Temperature Resistance: Take into consideration operating temperature range.

-

Flexibility: Decision of flexibility depends on the requirements of installations.

-

Size and Length: Choose the right diameter and lengths to be used.

-

Chemical Compatibility: Pipes do not all be resistant to the same chemicals.

-

Temperature and Pressure limits: There are certain materials that are capable of deformation through heat or pressing.

-

Cost vs. Longevity: Stainless steel is expensive and strong, whereas PVC is cheap but might not be applicable to extreme conditions.

-

Maintenance: Pipes that can be more easily cleaned and replaced save on time.

Common Applications of Chemical Pipe Solutions

The demand for durable chemical-resistant pipes extends across industries such as:

-

Water Treatment Plants: For transferring treatment chemicals safely.

-

Petrochemical Refineries: Handling fuels, solvents, and high-pressure fluids.

-

Pharmaceutical Manufacturing: Ensuring clean and safe chemical processes.

-

Food & Beverage Industry: Sanitary-grade pipes that resist contamination.

Conclusion

Industrial chemical handling demands more than just standard piping, it requires specialized pipe solutions that are resistant, reliable, and safe. From stainless steel and HDPE to PVC and CPVC, each option has its strengths and limitations.

Selecting the right solution depends on your application, budget, and compliance requirements. By investing in the right piping system, industries can avoid costly downtime, ensure safety, and maintain smooth operations for years to come.

When it comes to industrial chemical handling, choosing the right piping solutions is critical for safety, efficiency, and long-term performance. At Scotto Pipes, we take pride in manufacturing high-quality PVC pipes, uPVC pipes, suction pipes, and garden pipes that meet the diverse demands of industries and commercial applications. Designed for durability, chemical resistance, and ease of installation, our products provide reliable solutions for transporting fluids in even the most challenging environments.

FAQs About Industrial Pipe Solutions

Q1. What type of pipe is best for chemical handling?

Stainless steel, PVC, CPVC, HDPE, and PVDF are the most reliable choices depending on chemical type and conditions.

Q2. Are PVC pipes safe for chemicals?

Yes, PVC pipes are resistant to many acids and alkalis. However, for high-temperature chemicals, CPVC or stainless steel is preferred.

Q3. What is the lifespan of industrial chemical pipes?

It varies, PVC may last 10–15 years, HDPE up to 50 years, and stainless steel even longer with proper maintenance.

Q4. How do I choose the right pipe solutions for my facility?

Consider the type of chemical, flow requirements, temperature, pressure, and cost. Consulting an expert ensures the best fit.