Sizing of the suction pipelines, their length, and the area of location are very important parameters that influence the performance level of your water pump, its efficiency, as well as its durability. High losses in the suction pipe may even lower the performance of the pumps by half and lead to early malfunctions of the pump by falling into cavitation. This is a complete guideline consisting of professional suggestions on how best to select, size as well as install suction pipes and ensure the optimum functionality of your water pump system.

Understanding Suction Pipe Fundamentals

What is a Suction Pipe?

Your water pump is connected to the water source by a suction pipe. This provides the flow channel through which the water gets into the inlet of your water pump. In contrast to positive-pressure-use pipes of the discharge type, the water suction pipe are required to be able to withstand negative pressure (vacuum) without collapsing and still possess ideal flow characteristics. PVC suction hose and flexible suction hose types are commonly used in various applications.

Why the Right Suction Pipe Matters

The water coming into your source will enter into the suction pipes, which run between your water source and the water pump; they are very important in facilitating effective transfer of water. A deficient irrigation pump suction hose may lead to:

-

Cavitation Problems: Cavitation problems occur in a wrongly sized and/or positioned pump, likely to cause damage to the pump due to entering air bubbles.

-

Increased Water Flow: Pipes are too short or too small, which results in unwanted friction.

-

Wear and Tear on the Pumps: When improper alignment is done to the pipes, it may cause undue pressure to the pump motor, resulting in a shorter lifespan of the pump.

-

Pump Wear and Tear: Take your time and energy to choose the right pipe suction pump at the initial stage; this will save you money and headaches in the future.

How to Size a Suction Pipe for a Water Pump

One of the most critical factors in choosing a suction pipe is getting the size right. Water pump suction pipe size impacts water flow rate, pressure, and overall pump performance.

1. Understand Your Pump's Flow Rate

To size your suction pipe, the first thing you should do is to examine the flow rate that is propounded by your pump, and this is usually given in terms of gallons per minute (GPM) or liters per second (L/s). This is a value which is used to minimize the size of the diameter of the water line suction pump so that it may be used to transfer the amount of water normally without limitations.

Example: A flow rate of 50 GPM typically requires a pipe diameter of at least 1.5 inches. For higher flow rates, larger diameters are necessary.

2. Match Pipe Size to Pump Suction Port

Make sure that the diameter of the suction pipe for water pump is the same as or bigger than the suction port of the pump. Use of undersized hose pipe leads to the creation of bottlenecks, making water flow difficult and consequently the inefficiency in the system.

3. Consider Velocity Limits

The flow of water inside a suction pipe can probably not be more than 5 feet per second. During excessive velocity, friction losses are aggravated, and cavitation may be generated. To check compatibility and calculate water velocity, use the following formula:

Water Velocity (ft/s) = Flow Rate (GPM) ÷ (Pipe Cross-Sectional Area × 7.48)

Critical Performance Factors

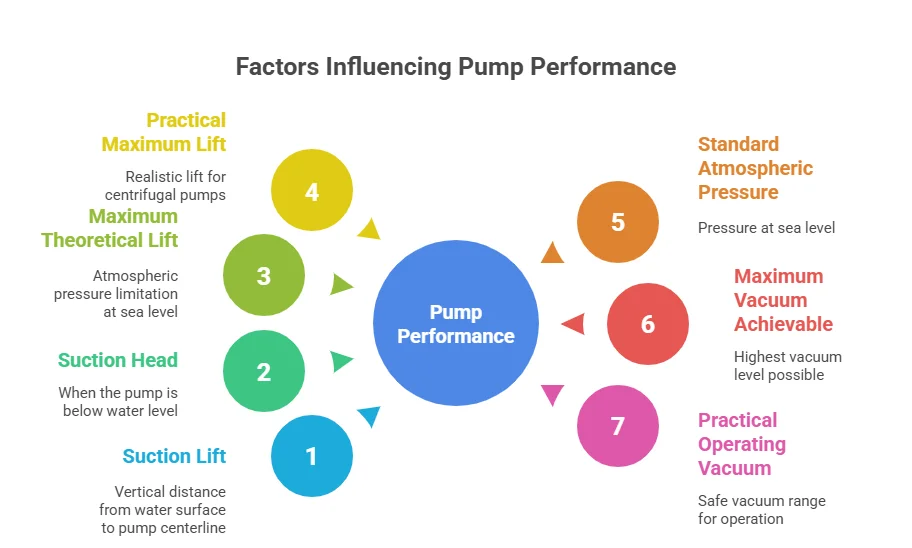

Suction Lift vs. Suction Head

-

Suction lift: Vertical distance from water surface to pump centerline (negative pressure)

-

Suction head: When the pump is below water level (positive pressure)

-

Maximum theoretical lift: 33.9 feet at sea level (atmospheric pressure limitation)

-

Practical maximum lift: 25 feet for most centrifugal pumps

Vacuum Requirements

-

Standard atmospheric pressure: 14.7 PSI at sea level

-

Maximum vacuum achievable: 29.92 inches of mercury

-

Practical operating vacuum: 20-25 inches of mercury

-

Safety margin: 15-20% below maximum theoretical lift

Suction Pipe Sizing Guide

Pipe Diameter Selection Formula

Basic Sizing Rule: Suction pipe diameter should be one size larger than the pump inlet diameter.

Standard Pump Inlet to Suction Pipe Sizing:

-

2-inch pump inlet → 3-inch suction pipe

-

3-inch pump inlet → 4-inch suction pipe

-

4-inch pump inlet → 5-inch or 6-inch suction pipe

-

6-inch pump inlet → 8-inch suction pipe

-

8-inch pump inlet → 10-inch suction pipe

Velocity-Based Sizing Method

Recommended Suction Velocities:

-

Optimal range: 4-7 feet per second

-

Maximum velocity: 8 feet per second

-

Deep well applications: 3-5 feet per second

-

Short suction runs: Up to 10 feet per second acceptable

Velocity Calculation Formula:

Velocity (fps) = (Flow Rate GPM × 0.321) / (Pipe Diameter inches)²

Example Calculation:

-

Flow rate: 100 GPM

-

Pipe diameter: 4 inches

-

Velocity = (100 × 0.321) / (4)² = 32.1 / 16 = 2.0 fps

Result: Too slow - increase to 6-inch pipe for optimal performance

Flow Rate Based Sizing Chart

Recommended Suction Pipe Diameters by Flow Rate:

| Pump Flow Rate (GPM) | Minimum Pipe Diameter | Recommended Diameter | Maximum Velocity (fps) |

|---|---|---|---|

| 10-25 GPM | 2 inches | 3 inches | 6.5 |

| 25-50 GPM | 3 inches | 4 inches | 7.0 |

| 50-100 GPM | 4 inches | 5 inches | 6.8 |

| 100-200 GPM | 5 inches | 6 inches | 7.2 |

| 200-400 GPM | 6 inches | 8 inches | 6.9 |

| 400-800 GPM | 8 inches | 10 inches | 7.1 |

| 800-1500 GPM | 10 inches | 12 inches | 6.8 |

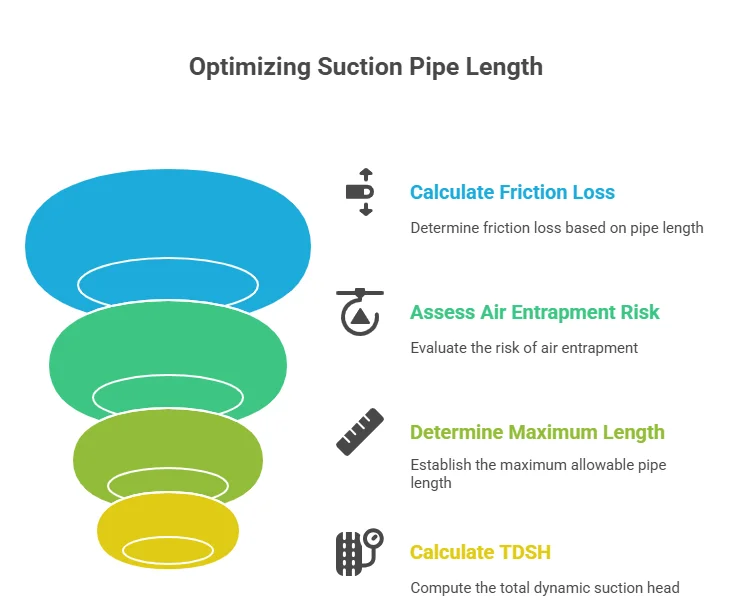

Suction Pipe Length Calculations and System Design

Maximum Suction Length Limitations

1. Horizontal Length Impact on Suction Lift:

-

Every 10 feet of horizontal PVC pipeline reduces lift capacity by approximately 1 foot

-

Friction losses accumulate with length and fittings

-

Longer pipes increase risk of air entrapment and cavitation

2. Practical Length Guidelines:

-

Maximum total length: 20–30 feet for optimal performance

-

Preferred length: Under 15 feet when possible

-

Deep well applications: Minimize horizontal runs

-

Surface water sources: Keep as short and straight as possible

Friction Loss Calculations

Friction Loss Formula (Hazen-Williams):

Head Loss (ft) = 10.67 × L × (Q^1.85) / (C^1.85 × D^4.87)

Where:

-

L = Length of pipe (feet)

-

Q = Flow rate (GPM)

-

C = Roughness coefficient (150 for new PVC, 130 for used)

-

D = Internal diameter (inches)

Friction Loss per 100 Feet of Pipe:

| Flow Rate (GPM) | 3-inch Pipe | 4-inch Pipe | 6-inch Pipe | 8-inch Pipe |

|---|---|---|---|---|

| 50 | 3.2 ft | 1.1 ft | 0.2 ft | 0.1 ft |

| 100 | 11.8 ft | 4.0 ft | 0.8 ft | 0.2 ft |

| 200 | 42.5 ft | 14.2 ft | 2.8 ft | 0.8 ft |

| 500 | – | – | 16.2 ft | 4.5 ft |

Total Dynamic Suction Head (TDSH) Calculation

TDSH Components:

-

Static suction lift: Vertical distance from water to pump

-

Friction losses: Pipe, fittings, and components

-

Velocity head: Kinetic energy requirement

-

Safety factor: 10–15% additional margin

TDSH Formula:

TDSH = Static Lift + Friction Losses + Velocity Head + Safety Factor

Example Calculation:

-

Static lift: 15 feet

-

Friction loss (100 GPM, 4-inch pipe, 20 feet): 0.8 feet

-

Velocity head (5 fps): 0.4 feet

-

Safety factor (10%): 1.6 feet

-

Total TDSH: 17.8 feet

Suction Pipe Components and Accessories

Essential Suction Line Components

1 Foot Valves:

-

Maintain pump prime and prevent backflow

-

Types: Flapper, swing, and ball check

-

Same diameter as suction pipe

-

Install at lowest point of suction line with proper submergence

2. Strainers:

-

Basket strainers: Easy maintenance

-

Y-strainers: Compact for tight spaces

-

Screen area: 3 - 4x pipe cross-section

-

Mesh size: 20 - 40 mesh standard

3. Suction Gauges:

-

Compound gauges (-30 to +15 PSI)

-

Mount close to pump inlet

-

Monitor suction pressure and vacuum

Air Removal Systems

Automatic air release valves and vacuum pumps for priming help maintain prime in deep well applications. The use of polyvinyl chloride pipes and PVC suction hose ensures longevity and consistent performance.

1. Manual Air Bleeds:

-

Install at high points in suction line

-

Use ball valves for easy operation

-

Essential for initial pump priming

-

Regular maintenance access required

2. Automatic Air Release Valves:

-

Continuous air removal during operation

-

Prevent air accumulation in long runs

-

Install at all high points in the system

-

Choose corrosion-resistant materials

3. Vacuum Pumps for Priming:

-

Electric or manual operation

-

Essential for deep well applications

-

Permanent installation on critical systems

-

Size based on suction line volume

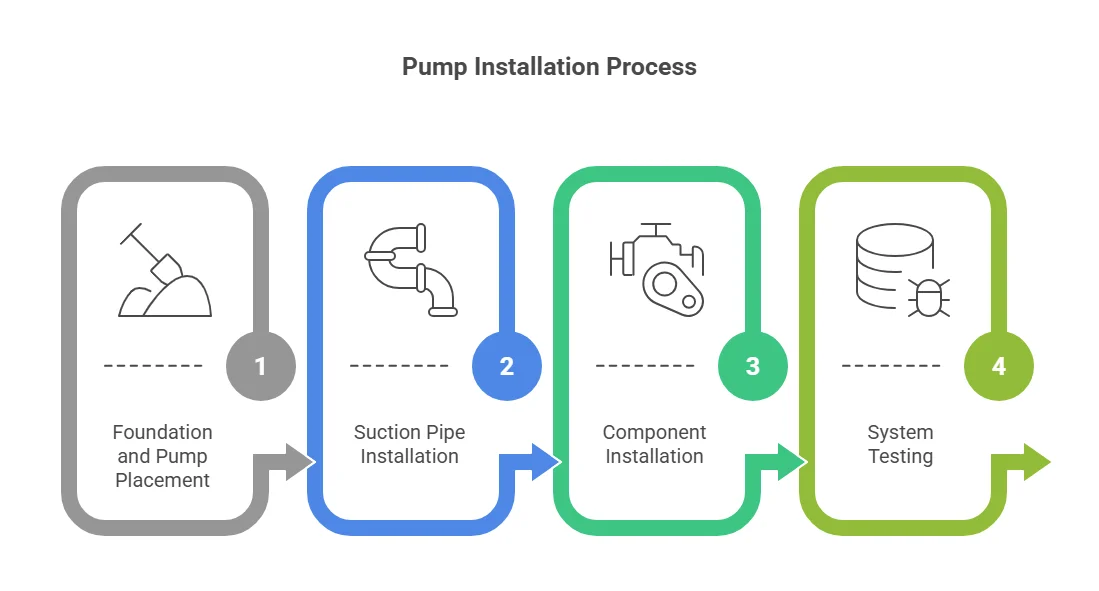

Installation and Commissioning Procedures

Ensure proper connection of the PVC pipeline and accessories to reduce the chance of cavitation and air leaks. Also, ensure strainers and suction pipes are cleaned and primed for effective system startup.

Pre-Installation Checklist

1. Site Preparation:

-

Confirm water availability and quality

-

Check foundation and pump placement

-

Verify local codes and permits

-

Ensure proper electrical setup

2. Material Inspection:

-

Check pipe specs and pressure ratings

-

Inspect all fittings and seals

-

Test valves and strainers pre-installation

Step-by-Step Installation Process

1. Foundation and Pump Placement:

-

Pour concrete foundation with proper anchor bolts

-

Allow concrete to cure for a minimum 7 days before pump installation

-

Level pump and check alignment specifications

-

Install vibration isolation pads if required

2. Suction Pipe Installation:

-

Start at water source and work toward pump

-

Maintain proper slope and support spacing

-

Use backing rings and gaskets for flanged connections

-

Install expansion joints at appropriate intervals

3. Component Installation:

-

Install foot valve at proper depth and orientation

-

Connect strainer with adequate clearance for cleaning

-

Mount pressure gauges and air release valves

-

Test all connections for proper sealing

4. System Testing:

-

Fill suction line with water for initial priming

-

Start pump and monitor suction pressure

-

Check for air leaks and vibration issues

-

Verify design flow rate and pressure performance

Commissioning and Performance Testing

Effective commissioning maintains that the pump system is effective since day one. To test system performance and be ready to use it in the future, follow these start-up procedures, performance check and documentation.

Initial Startup Procedures:

-

Fill suction line completely with water

-

Close all discharge valves initially

-

Start pump and gradually open discharge valve

-

Monitor suction gauge for proper vacuum levels

-

Check for cavitation noise or vibration

Performance Verification:

-

Measure actual flow rate vs. design requirements

-

Record suction and discharge pressures

-

Monitor pump current draw and efficiency

-

Document system operating parameters

Final System Documentation:

-

Create as-built drawings with pipe sizes and locations

-

Document all component specifications and settings

-

Establish maintenance schedule and procedures

-

Train operators on proper system operation

Maintenance and Troubleshooting

Breakdowns are avoided by regular maintenance and to maintain the optimum performance of a pump. This schedule can help you be one step ahead of these problems by checking them weekly, monthly, and on an annual basis, with included troubleshooting procedures of popular issues.

Preventive Maintenance Schedule

Weekly and monthly checks of water suction pipe systems can catch early signs of wear or blockage. Regularly inspect all hose pipe connections and seals.

1. Weekly Checks:

-

Monitor suction pressure gauge readings

-

Listen for unusual pump noise or vibration

-

Check water source level and availability

-

Inspect visible piping for leaks or damage

2. Monthly Maintenance:

-

Clean strainer basket and inspect for damage

-

Check foot valve operation and sealing

-

Test air release valves for proper function

-

Record system performance data

3. Annual Service:

-

Pressure test entire suction system

-

Replace gaskets and seals as needed

-

Inspect and clean all components

-

Update system documentation

Troubleshooting Guide

Have pump problems? This is a problem-solving tool to guide on how to detect and fix simple but common problems such as low flow rate, cavitation and loss of prime, by making simple checks and providing simple solutions.

Low Flow Rate Problems:

-

Check suction pressure: Should be 5-15 inches mercury vacuum

-

Inspect strainer: Clean if pressure drop exceeds 5 PSI

-

Verify pump prime: May need manual priming or foot valve replacement

-

Check for air leaks: Pressure test suction line

Excessive Cavitation:

-

Reduce suction lift: Lower pump or increase water level

-

Increase pipe size: Reduce velocity below 7 fps

-

Remove restrictions: Clean strainer, open valves fully

-

Check pump curve: Verify operating point is within acceptable range

Frequent Loss of Prime:

-

Replace foot valve: If allowing backflow

-

Seal air leaks: Pressure test and repair joints

-

Check water source: Ensure adequate supply and level

-

Install priming system: For problematic installations

Scotto Pipes: Reliable Partner for Agricultural Irrigation

Scotto Pipes is a well-known manufacturer and exporter of high-quality PVC, uPVC, suction and garden pipes aimed at fulfilling the multiple irrigation requirements of contemporary farming. They are a brand to be reckoned with and known to be durable and perform consistently, so that their products can be used in farms, small gardens, to even very big commercial fields.

Scotto pipes offers long-term and effective supply of water flow systems through certified pressure ratings, vast availability of products, and professional technical assistance. Also, the farmers and contractors all over India and across the world count on Scotto to provide quality irrigation pump suction hose and piping service that enhances growing of crops to increase crop yields and also to save on water loss.

Conclusion

Selection of a suitable suction pipe is essential in enhancing the efficiency of the pump so as to maintain a perfect water flow as well as reducing maintenance costs in any agricultural or industrial installation. Whether you own a small-scale farm or a commercial-sized farm, knowing about the types of pipes, the material and the best way to install all will save you money from making the wrong decisions. Never make your pipes with unqualified manufacturers but with qualified manufacturers such as Scotto Pipes, which are manufactured with quality, durability and excellent support. An excellent selected suction pipe does not only mean a connection, they are the backbone of your wateration.