Introduction

When planning a plumbing system, water distribution network, or industrial piping project, selecting the right type of pipe is one of the most critical decisions you can make. The choice between CPVC pipes and PVC pipes is often confusing for homeowners, engineers, and plumbers alike, because while both are made of polyvinyl chloride derivatives, their properties, applications, and installation requirements differ significantly. Understanding the distinctions in temperature tolerance, chemical resistance, durability, and fitting requirements ensures that your system remains reliable for years to come.

For high-quality and reliable piping solutions, companies like Scotto Pipes PVC, UPVC, Garden, and Suction Pipes Manufacturer and Supplier provide a comprehensive range of pipes and fittings suitable for residential, commercial, and industrial applications. Whether you need PVC pipeline for irrigation, flexible PVC pipe for complex layouts, or CPVC pipework for hot water supply, using trusted products ensures safety, efficiency, and durability.

This guide will help you understand the key differences between PVC pipes and CPVC pipes, along with practical tips for installation, applications, and maintenance.

What Are CPVC and PVC Pipes?

PVC Pipes

Polyvinyl chloride pipes (PVC) are rigid, lightweight pipes manufactured using polymerized vinyl chloride monomers. They are primarily designed for cold water distribution, drainage systems, and irrigation projects. PVC is popular because of its cost-effectiveness, long service life, corrosion resistance, and ease of installation. PVC pipes are often available as white PVC pipe, white plastic pipe, or transparent varieties, and are commonly paired with PVC fittings to create strong and leak-proof joints.

Practical examples of PVC applications:

-

Cold water supply lines in residential and commercial buildings, ensuring efficient water flow without the risk of deformation.

-

PVC pipeline for gardens, parks, and agricultural irrigation, where durability against moisture and chemicals is essential.

-

Wastewater drainage systems that resist corrosion and long-term wear.

-

Use in PVC hose setups for flexible water distribution or temporary water transfer applications.

CPVC Pipes

Chlorinated polyvinyl chloride (CPVC) pipes are chemically modified PVC pipes where additional chlorine molecules are added through a chlorination process. This modification enhances heat and chemical resistance, allowing CPVC pipes to handle higher water temperatures safely. CPVC pipes are typically off-white or cream-colored and must be installed using CPVC fittings, which are specially designed to ensure secure connections and prevent leaks under high-temperature conditions.

Practical examples of CPVC applications:

-

Hot water distribution in kitchens, bathrooms, and commercial facilities where temperatures can exceed standard PVC limits.

-

Industrial chemical transport lines, taking advantage of CPVC’s superior resistance to acids, alkalis, and salts.

-

Fire sprinkler systems that require both heat resistance and durability.

-

Residential CPVC pipework installations, including 1/2 CPVC pipe connections for sinks, showers, and water heaters.

Key Differences Between CPVC and PVC Pipes

Understanding the differences between PVC pipes and CPVC pipes can prevent costly mistakes in plumbing or industrial applications. Here’s a detailed comparison:

| Feature | PVC Pipes | CPVC Pipes |

|---|---|---|

| Temperature Resistance | Designed for cold water, typically up to 140°F (60°C). Using PVC for hot water can cause warping or leaks over time. | Engineered for hot and cold water systems, capable of handling temperatures up to 200°F (93°C) without losing structural integrity. |

| Chemical Resistance | Resistant to common acids and alkalis, but prolonged exposure to certain solvents can cause deterioration. | Enhanced chemical resistance makes it ideal for industrial liquid handling, including acids, bases, and salts. |

| Flexibility | Rigid and less forgiving, making installation around curves more challenging unless flexible PVC pipe is used. | Slightly flexible due to chlorination, allowing easier installation in complex layouts. |

| Installation | Can be installed with standard PVC pipe fittings using solvent cement. Easy and fast to cut, join, and secure. | Requires CPVC fittings and specialized solvent cement to prevent leaks. Proper curing time is critical for long-term performance. |

| Cost | More economical upfront, making it popular for large-scale irrigation and drainage projects. | Higher initial cost, but offers long-term durability and suitability for high-temperature and chemical-intensive applications. |

| Color | White or transparent, widely recognized in residential and commercial settings. | Off-white or cream, designed to differentiate it from standard PVC for hot water and industrial use. |

Practical Tip: For irrigation lines, landscaping, or projects requiring slight bends, use flexible PVC pipe. For hot water systems in kitchens or bathrooms, CPVC pipe for hot water is strongly recommended to avoid pipe damage and ensure safe water delivery.

Temperature and Pressure Tolerance

Temperature and pressure handling capabilities are crucial when selecting pipes:

-

PVC Pipes: Ideal for cold water and low-pressure systems. Temperatures above 140°F (60°C) can cause PVC pipe deformation, leakage, or failure. For example, using 1 PVC pipe to supply hot water to a kitchen sink may lead to pipe sagging or joint failure over time.

-

CPVC Pipes: Engineered for hot water applications, CPVC pipework withstands high temperatures and moderate to high pressure. This makes 1/2 CPVC pipe a reliable choice for connecting water heaters, boilers, or hot water showers without risk of leaks or cracking.

Tip: Always check the pressure rating for both PVC and CPVC pipes. Industrial or commercial installations often require higher pressure-rated pipes.

Chemical Resistance and Durability

Chemical exposure can significantly affect pipe lifespan:

-

PVC Pipes: Resistant to most common household and agricultural chemicals, but exposure to hot liquids, strong acids, or industrial solvents can reduce durability. Regular maintenance is recommended to monitor potential wear in chemical-heavy environments.

-

CPVC Pipes: Offers superior resistance to chemicals, including acids, bases, and salts, making it suitable for industrial CPVC pipework or laboratories. Its heat resistance also prevents warping or degradation when transporting hot or aggressive liquids.

Example: In a factory transporting hot chemical solutions, CPVC pipe and fittings are preferable over PVC to maintain safety and long-term performance.

Pipe Installation and Maintenance

Proper installation is key to ensuring the longevity, safety, and leak-free performance of both PVC pipes and CPVC pipes. Correct methods prevent costly repairs, minimize maintenance, and ensure your plumbing system functions efficiently for years.

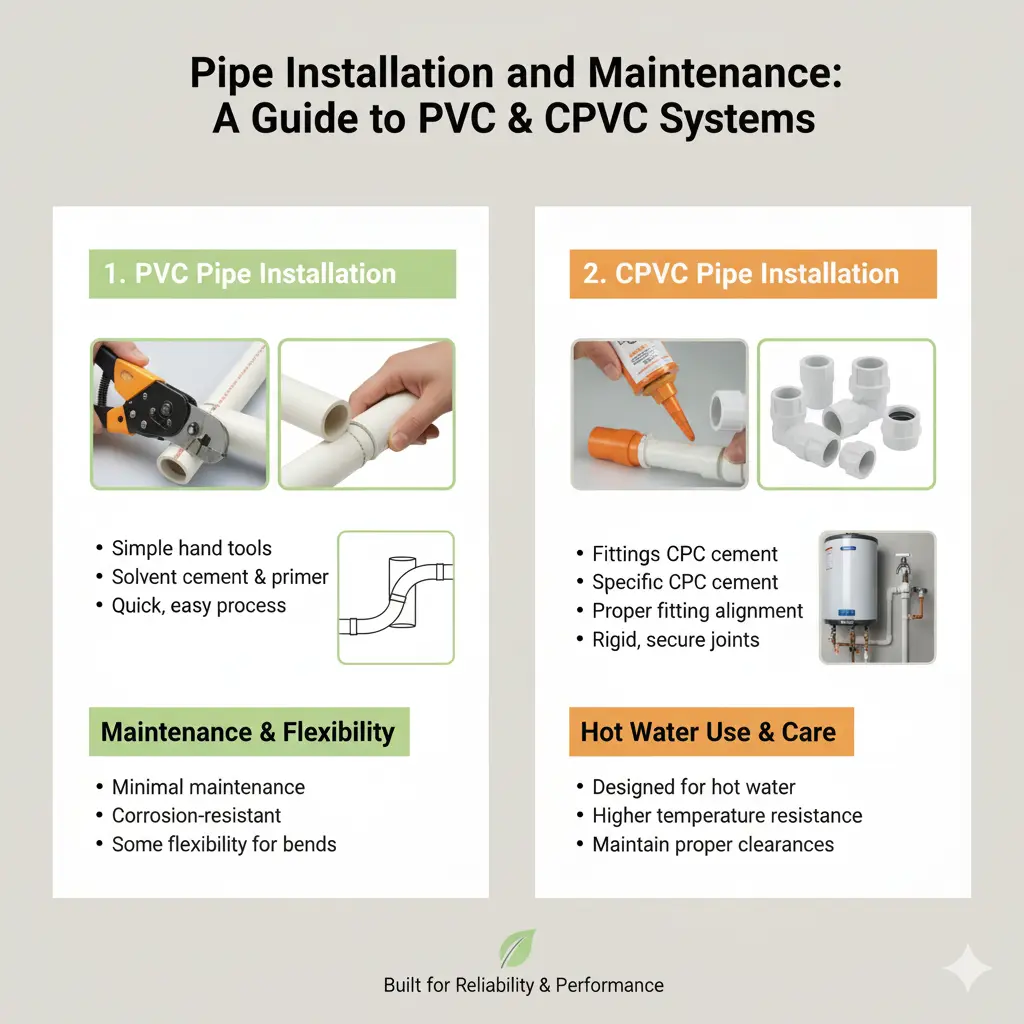

PVC Pipe Installation

-

Cutting and Joining: PVC pipes can be easily cut using standard pipe cutters or a fine-toothed saw. After cleaning and deburring the edges, pipes are joined with PVC pipe fittings using solvent cement, which chemically fuses the pipe and fitting to create a strong, durable, and leak-proof connection suitable for cold water or drainage systems.

-

Maintenance: Cold water or drainage systems using PVC pipes generally require minimal upkeep, but periodic inspection for joint leaks, physical damage, or sediment buildup is recommended to ensure long-term performance.

-

Flexibility: Using flexible PVC hoses alongside rigid pipes allows easy navigation around corners, obstacles, or irregular layouts, reducing the need for multiple elbow fittings and minimizing potential leak points in temporary or adjustable water systems.

CPVC Pipe Installation

-

Fittings and Cement: Installing CPVC requires CPVC fittings and specially formulated solvent cement designed to handle chlorinated polyvinyl chloride. This ensures secure, leak-proof joints capable of withstanding high temperatures and pressures in both residential and commercial applications.

-

Care During Installation: Extra care is needed to avoid twisting, over-tightening, or forcing heat-sensitive CPVC joints, which can weaken the connection. Proper alignment before curing is essential to maintain strength and reliability.

-

Hot Water Use: CPVC pipe for hot water is ideal for applications where repeated heating occurs, such as 1/2 CPVC pipe in kitchens, bathrooms, or hot water loops, providing durability without warping, cracking, or leaking.

Pro Tip: Always allow sufficient curing time for solvent cement before applying water pressure, as curing time varies by pipe diameter and ambient temperature. Follow the manufacturer’s guidelines carefully for temperature-specific installation, and avoid applying stress to freshly installed pipes to ensure leak-free joints and maximum lifespan.

Applications: Where to Use PVC vs CPVC

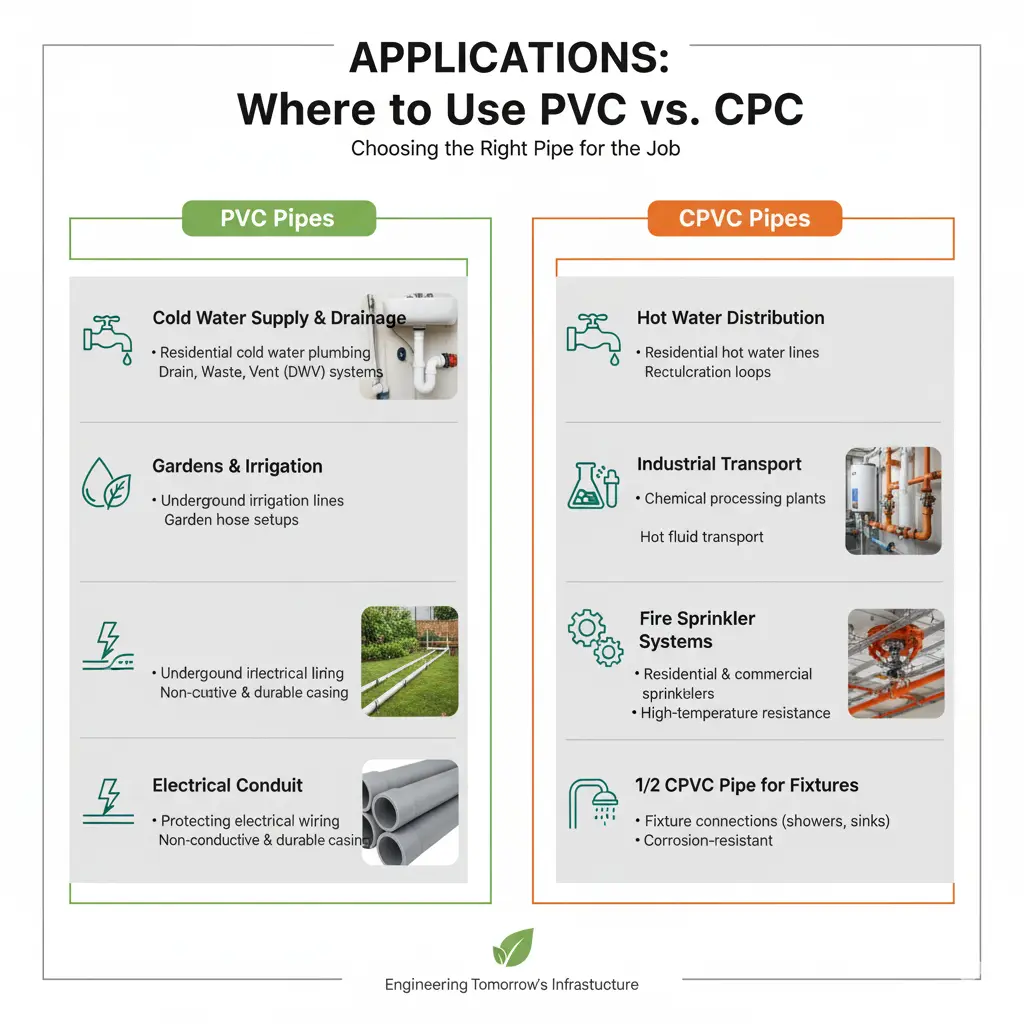

PVC Pipes

-

Cold Water Supply and Drainage: Ideal for delivering cold water in homes, offices, and schools, PVC pipes ensure a reliable, corrosion-resistant system for everyday water use.

-

PVC Pipeline for Gardens and Irrigation: Perfect for irrigation systems, gardens, parks, and agricultural fields, PVC pipeline offers durability, low maintenance, and easy installation even over long distances.

-

PVC Hose Setups: PVC hoses provide flexible solutions for temporary water transport or movable water systems, helping navigate around obstacles without requiring complex fittings.

-

Electrical Conduit Applications: PVC pipes are widely used as electrical conduits in residential and commercial buildings due to their insulating properties, lightweight nature, and ease of installation.

CPVC Pipes

-

Hot Water Distribution: CPVC pipes are designed for hot water supply in kitchens, bathrooms, and commercial buildings, capable of handling higher temperatures without warping or leaks.

-

Industrial Chemical Transport and Hot Water Loops: CPVC pipework is highly resistant to chemicals, making it suitable for industrial processes, hot water loops, and systems exposed to acids, bases, or salts.

-

Fire Sprinkler Systems: CPVC pipes provide the heat resistance and durability needed for fire sprinkler systems, ensuring safe and reliable operation under high-temperature conditions.

-

1/2 CPVC Pipe for Fixtures: Smaller diameter pipes like 1/2 CPVC pipe are ideal for connecting sinks, showers, and water heaters, delivering consistent hot water without risk of deformation.

Example: In a multi-story building, using CPVC pipe for hot water prevents pipe sagging, leaks, and potential accidents, offering a safer and longer-lasting alternative to standard PVC pipes in high-temperature applications.

Cost Comparison

While PVC pipes are cheaper and widely used for cold water and irrigation, CPVC pipes have a higher upfront cost due to enhanced durability, heat, and chemical resistance. However, the long-term benefits often justify the price: fewer replacements, less maintenance, and safer hot water delivery.

Practical Tip: Choose PVC pipes for large-scale irrigation or drainage systems where temperature is not an issue. Opt for CPVC pipework in kitchens, bathrooms, or industrial setups where hot water or chemical exposure is expected.

Installation Tips for Maximum Lifespan

-

Use the recommended PVC pipe and fittings or CPVC pipe and fittings to avoid leaks.

-

Avoid bending PVC pipes beyond their tolerance; use flexible PVC pipe for curved layouts.

-

Allow proper curing time for solvent cement to ensure long-lasting joints.

-

For hot water systems, use CPVC pipe for hot water with correct diameters like 1/2 CPVC pipe for sinks or showers.

-

Regularly inspect connections, joints, and fittings to detect early signs of wear, especially in chemical or high-temperature environments.

Conclusion

Selecting between CPVC pipes and PVC pipes requires careful consideration of temperature, chemical exposure, installation, and budget. PVC pipes are suitable for cold water systems, drainage, and irrigation, offering affordability and ease of installation. CPVC pipes, designed for hot water and chemical-intensive applications, provide higher temperature resistance, durability, and long-term reliability.

By understanding the key differences in temperature tolerance, chemical resistance, flexibility, and installation requirements, you can choose the right pipe and fittings for your residential, commercial, or industrial plumbing needs.

FAQs

Q1: Can CPVC pipes be used for cold water applications?

Yes, CPVC pipes are versatile and safe for cold water systems. They are mainly designed for hot water but perform equally well for cold water distribution.

Q2: Is PVC suitable for hot water?

No. PVC has low heat tolerance and can warp, crack, or leak if used for hot water applications.

Q3: Can PVC and CPVC pipes be connected together?

Direct connections are not recommended. CPVC fittings and PVC fittings require different solvents and joint types to maintain leak-proof performance.

Q4: What is the difference between white PVC pipe and CPVC pipe?

White PVC pipe is typically used for cold water or drainage. CPVC pipes, usually off-white, are designed to withstand higher temperatures and chemical exposure.

Q5: Which pipe is more durable?

For hot water and chemical applications, CPVC pipes are more durable. For cold water supply, irrigation, and drainage, PVC pipes provide cost-effective durability.