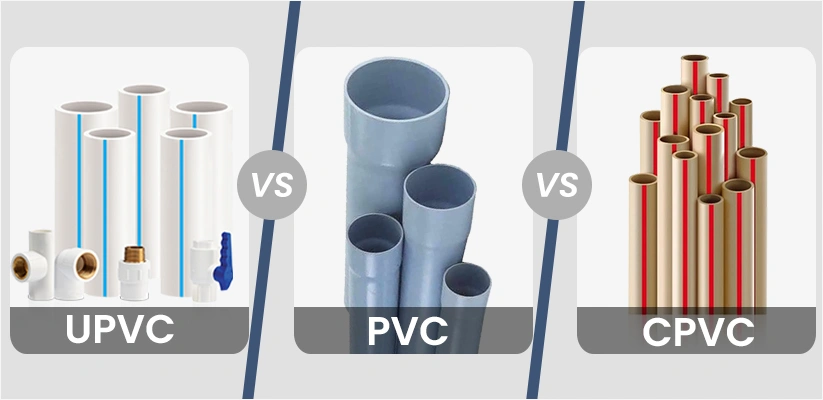

Selecting the right pipe materials is a crucial decision for any plumbing or water management project. Whether it is residential construction, industrial infrastructure, or agricultural systems, choosing the wrong pipe can lead to leakage, inefficiency, and frequent maintenance. Among modern plastic pipes, PVC, uPVC, and CPVC are the most commonly used options.

This guide offers a detailed comparison of PVC vs uPVC vs CPVC, covering performance, applications, durability, and installation. If you are planning a water supply, drainage, or irrigation system and want clarity on CPVC pipes, uPVC pipes, and PVC pipes, this article will help you make an informed choice.

Understanding PVC Pipes

PVC pipes (Polyvinyl Chloride pipes) are one of the most widely used plumbing pipes globally. Known for affordability and durability, PVC is primarily used in drainage and cold water applications.

PVC is a type of rigid PVC that offers high strength while remaining lightweight. Due to its resistance to corrosion and chemicals, PVC pipes are commonly used for drainage pipes, irrigation systems, and sewage networks.

Key Characteristics of PVC Pipes

-

Rigid structure with good impact resistance

-

Compatible with standard PVC fittings

-

Suitable for cold water pipes and drainage

-

Cost-effective for large-scale installations

PVC pipes are not designed for high-temperature water, which limits their use in hot water plumbing.

Understanding uPVC Pipes

uPVC pipes (Unplasticized Polyvinyl Chloride) are an advanced version of PVC without added plasticizers. This makes them stronger, more rigid, and environmentally safer.

uPVC pipes are commonly used in water supply, drainage, and outdoor plumbing systems. Their high chemical resistance makes them suitable for both residential and commercial applications.

Key Characteristics of uPVC Pipes

-

Higher rigidity than standard PVC

-

Strong resistance to chemicals and UV exposure

-

Excellent flow characteristics

-

Commonly used in cold water pipes and sewage systems

Because of their rigidity and strength, uPVC pipes are often preferred in underground installations and structural plumbing.

Understanding CPVC Pipes

CPVC pipes (Chlorinated Polyvinyl Chloride) are modified PVC pipes that undergo chlorination to improve heat resistance. This process allows CPVC pipes to handle higher temperatures, making them ideal for hot water pipes.

CPVC is widely used in residential and commercial plumbing where both hot and cold water supply is required.

Key Characteristics of CPVC Pipes

-

High resistance to heat and pressure

-

Suitable for hot and cold water supply

-

Durable and corrosion-resistant

-

Compatible with specialized pipe fittings

CPVC pipes are commonly used in internal plumbing systems where temperature stability is essential.

Key Differences Between PVC, UPVC, and CPVC

Understanding the differences between these materials helps in selecting the right solution for specific applications.

| Feature | PVC Pipes | UPVC Pipes | CPVC Pipes |

|---|---|---|---|

| Plasticizers | Present | Absent | Absent |

| Temperature Resistance | Low | Moderate | High |

| Strength & Rigidity | Moderate | High | High |

| Suitable for Hot Water | No | No | Yes |

| Common Uses | Drainage, irrigation | Cold water supply | Hot & cold water plumbing |

| Cost | Low | Medium | High |

PVC is ideal for cost-sensitive, low-temperature applications. UPVC offers enhanced strength and durability for cold water plumbing, while CPVC stands out for high-temperature and high-pressure systems.

PVC vs UPVC vs CPVC: Application-Based Comparison

Selecting the correct pipe depends heavily on the intended application:

-

Cold water pipes: UPVC pipes are ideal due to strength and safety

-

Hot water pipes: CPVC pipes are the best option

-

Drainage pipes and sewage pipes: PVC pipes are cost-effective and reliable

-

Irrigation pipes: PVC and UPVC are commonly used

-

Industrial plumbing pipes: CPVC offers superior chemical resistance

Environmental conditions, pressure requirements, and local building codes also play a crucial role in material selection.

Pipe Installation Guide and Ease of Handling

PVC and uPVC Pipe Installation

PVC and uPVC installation involves cutting, cleaning, and solvent welding. Proper alignment is crucial before bonding to ensure leak-free joints.

These pipes are easy to transport and handle due to their lightweight nature. Standard PVC fittings and accessories are widely available.

CPVC Pipe Installation

CPVC installation is similar to PVC but requires specific solvent cement and fittings designed for higher temperatures.

While CPVC installation may cost slightly more, it ensures long-term performance in hot water systems.

Durability and Lifespan Comparison

PVC pipes typically last 40–60 years when used for drainage and cold water applications. Their resistance to corrosion ensures stable performance over time.

uPVC pipes have a longer lifespan, often exceeding 50 years, especially in underground installations. Their rigid structure provides additional strength and reliability.

CPVC pipes offer a lifespan of 40–50 years, even under high-temperature conditions. This makes CPVC a reliable option for internal plumbing systems handling hot water.

Advantages and Limitations of PVC Pipes

PVC Pipes – Advantages

-

Affordable and widely available

-

Easy to install and maintain

-

Ideal for drainage and irrigation

PVC Pipes – Limitations

-

Not suitable for hot water

-

Lower strength compared to uPVC

Cost Comparison: PVC vs UPVC vs CPVC

Cost varies significantly when comparing PVC vs UPVC vs CPVC, not only in terms of material price but also installation and long-term maintenance. While PVC pipes are the most budget-friendly, UPVC and CPVC pipes offer better durability and performance for specific plumbing needs.

-

PVC pipes have the lowest cost, making them ideal for drainage pipes, irrigation pipes, and sewage pipes. They are easy to install, use affordable PVC fittings, and require minimal labor.

-

UPVC pipes are moderately priced and offer higher strength and pressure resistance, making them suitable for water supply and plumbing pipes with longer service life.

-

CPVC pipes are the most expensive due to their ability to handle hot water pipes and high temperatures, but they reduce failure and maintenance costs in hot water systems.

Overall, PVC pipes suit low-budget, cold-water applications, UPVC pipes balance cost and durability, and CPVC pipes provide long-term value for hot water plumbing.

Advantages and Limitations of UPVC Pipes

uPVC Pipes – Advantages

-

High rigidity and strength

-

Suitable for water supply and sewage pipes

-

Excellent chemical and UV resistance

uPVC Pipes – Limitations

-

Less flexible than PVC

-

Not suitable for hot water

Advantages and Limitations of CPVC Pipes

CPVC Pipes – Advantages

-

Suitable for hot and cold water pipes

-

High pressure and temperature resistance

-

Long-lasting and reliable

CPVC Pipes – Limitations

-

Higher cost than PVC and uPVC

-

Requires specialized fittings

How to Choose the Right Pipe Material

When selecting the right pipe, consider:

-

Type of application (water supply, drainage, irrigation)

-

Temperature requirements

-

Installation environment

-

Budget and long-term maintenance

PVC is best for drainage and irrigation, uPVC is ideal for cold water supply and sewage, while CPVC is the preferred choice for hot water plumbing.

Why Choose Scotto Pipes for PVC pipes and uPVC pipes Solutions

Scotto Pipes is committed to delivering high-quality PVC pipes and uPVC pipes engineered for long-term performance across residential, commercial, and industrial applications. With a strong focus on material quality, precision manufacturing, and compliance with industry standards, Scotto Pipes ensures reliable solutions for water supply, drainage, and irrigation systems.

Every product is designed to meet modern plumbing demands, offering excellent flow efficiency, high durability, and compatibility with standard pipe fittings. From cold water and drainage systems to high-temperature hot water pipes, Scotto Pipes provides dependable plastic pipes that perform consistently under varying pressure and environmental conditions.

Backed by strict quality control, advanced manufacturing processes, and technical expertise, Scotto Pipes is a trusted choice for contractors, builders, and infrastructure projects seeking durable and efficient plumbing pipes.

Conclusion

Understanding the differences between PVC vs uPVC vs CPVC helps you select the right solution for your plumbing needs. Each material serves a specific purpose, from drainage and irrigation to hot water supply systems.

Choosing high-quality pipe materials and proper pipe installation ensures durability, safety, and long-term performance. By selecting the right pipe for the right application, you can build efficient and reliable plumbing systems that stand the test of time.

People Also Ask (FAQs)

1. What is the main difference between PVC, uPVC, and CPVC?

The primary difference lies in temperature resistance and rigidity.

2. Which pipe is best for hot water supply?

CPVC pipes are best suited for hot water applications.

3. Are uPVC pipes safe for drinking water?

Yes, uPVC pipes are commonly used for potable water supply.

4. Which pipe material lasts the longest?

uPVC pipes generally offer the longest lifespan in structural plumbing systems.

5. Can PVC pipes be used for irrigation?

Yes, PVC pipes are widely used as irrigation pipes.