Choosing the right piping material is one of the most critical decisions when planning a water supply system for residential, commercial, or industrial applications, as it affects durability, water quality, long-term maintenance, and overall investment. Among the commonly used options, UPVC pipes and GI pipes are often compared due to their popularity and reliability in different settings. Both have unique properties, but understanding their strengths, weaknesses, and specific use cases is essential for homeowners, builders, and engineers who want a cost-effective and long-lasting plumbing solution.

What Are UPVC Pipes?

UPVC pipes, or unplasticized polyvinyl chloride pipes, are rigid, non-toxic, and chemically resistant pipes that have become the preferred choice for modern plumbing systems worldwide, especially in urban residential and commercial buildings. Unlike regular PVC pipes, unplasticized polyvinyl chloride contains no added plasticizers, making it significantly stronger, more rigid, and able to withstand moderate pressure and temperature fluctuations without deformation.

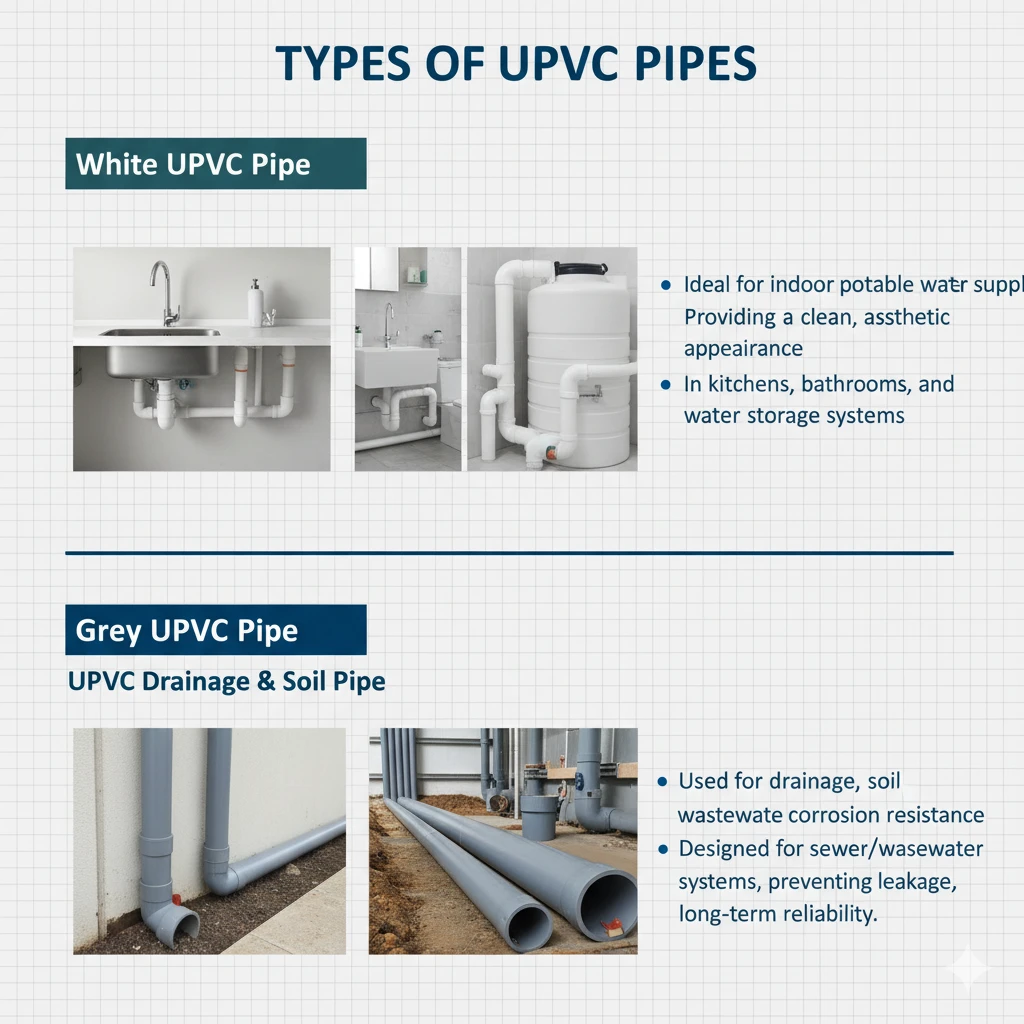

Types of UPVC Pipes:

-

White UPVC pipe: Ideal for indoor potable water supply, providing a clean, aesthetic appearance in kitchens, bathrooms, and water storage systems.

-

Grey UPVC pipe: Commonly used for drainage, soil management, and wastewater applications due to its durability and corrosion resistance.

-

UPVC drainage pipe & UPVC soil pipe: Specially designed for sewer and wastewater systems, preventing leakage and ensuring long-term reliability.

Key Features of UPVC Pipes:

-

Lightweight design allows easy transportation and handling during installation, reducing labor efforts and risk of damage.

-

Resistant to chemical corrosion, scaling, and rust, making it ideal for transporting clean water without contamination.

-

Compatible with UPVC pipe fittings and other pipeline accessories for creating complex plumbing layouts efficiently.

-

Long lifespan of 25–50 years, offering minimal maintenance costs compared to metal pipes.

-

Non-toxic and safe for drinking water applications, ensuring health and hygiene standards are maintained.

Applications of UPVC Pipes:

-

Residential water supply pipelines in apartments, houses, and commercial buildings.

-

Sewerage systems and drainage pipelines in urban infrastructure projects.

-

Agricultural irrigation systems due to its lightweight and corrosion-resistant nature.

-

Industrial piping for transporting non-corrosive liquids efficiently.

What Are GI Pipes?

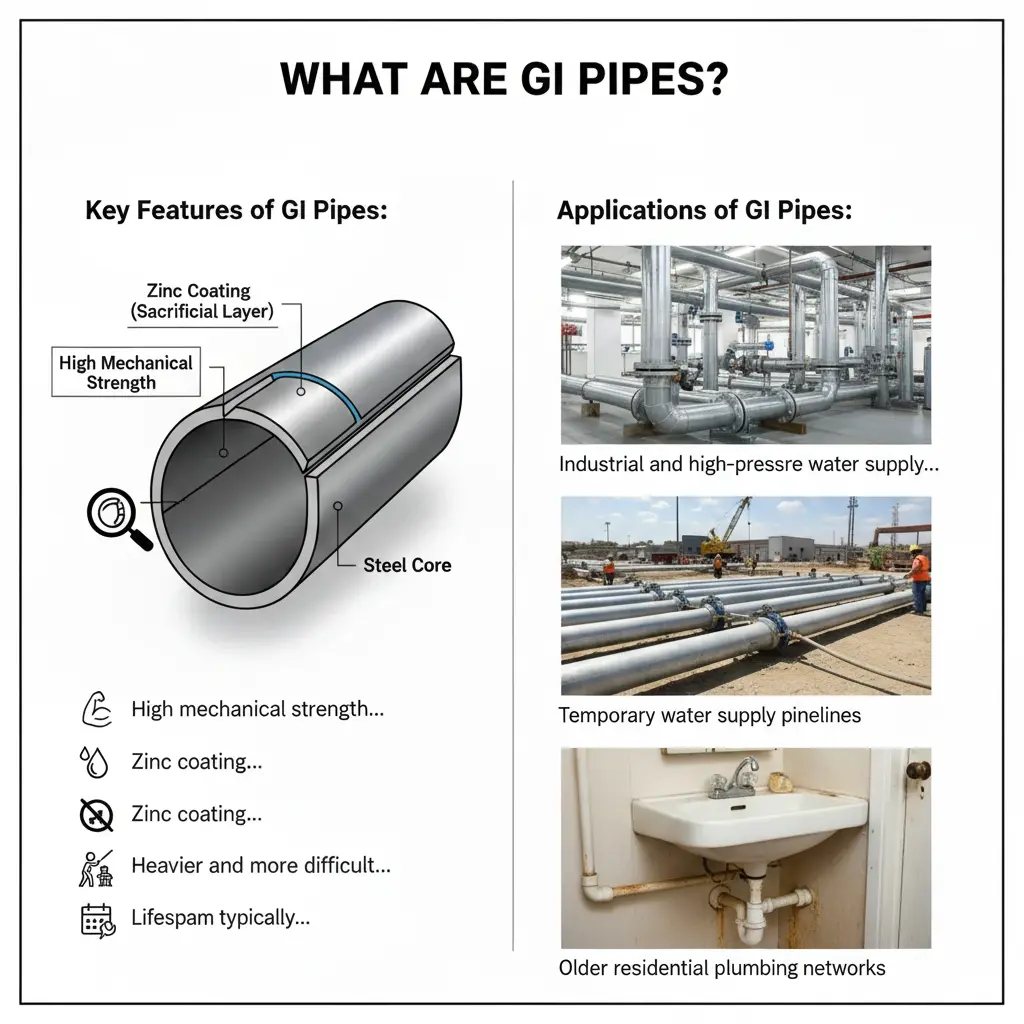

GI pipes, or galvanized iron pipes, are steel pipes coated with a layer of zinc to prevent rust and corrosion, making them historically popular for plumbing and water distribution in older buildings and industrial settings. These pipes have high mechanical strength and durability, which makes them suitable for pressurized water systems, but they come with certain limitations compared to modern alternatives like UPVC.

Key Features of GI Pipes:

-

High mechanical strength allows them to withstand heavy external loads and moderate water pressure without bending or breaking.

-

Zinc coating prevents immediate rust formation but can wear off over time, especially in contact with hard or acidic water, leading to internal corrosion.

-

Heavier and more difficult to handle compared to lightweight UPVC pipes, requiring additional support structures for horizontal installations.

-

Lifespan typically ranges from 15–30 years depending on water quality and environmental conditions, often requiring maintenance to extend longevity.

Applications of GI Pipes:

-

Industrial and high-pressure water supply systems where mechanical strength is crucial.

-

Temporary water supply pipelines at construction sites.

-

Older residential plumbing networks that were installed before UPVC became widely available.

UPVC Pipe vs GI Pipe: Detailed Comparison

Here’s an in-depth comparison highlighting all important aspects of UPVC pipework versus GI pipes to help you decide the best option for water supply:

| Feature | UPVC Pipes | GI Pipes |

|---|---|---|

| Material | Made from unplasticized polyvinyl chloride, providing rigidity and chemical resistance | Made from steel with a galvanized zinc coating, providing mechanical strength |

| Corrosion Resistance | Excellent, non-corrosive, does not rust or scale over time | Prone to rust, internal scaling, and corrosion, especially with hard water |

| Weight | Lightweight, easy to handle, transport, and install | Heavy, requiring additional support and more labor during installation |

| Installation | Quick and easy with uPVC fittings and solvent cement | Labor-intensive, requires threading, welding, or mechanical joints |

| Lifespan | 25–50 years depending on usage and maintenance | 15–30 years depending on water quality and environmental exposure |

| Maintenance | Minimal, occasional joint checks | High, requires regular inspection, cleaning, and anti-corrosion treatments |

| Pressure Handling | Suitable for moderate water pressure applications | Can handle high-pressure systems but may corrode internally over time |

| Temperature Tolerance | Can withstand temperatures up to 60°C | Can withstand higher temperatures but corrosion risk increases with heat |

| Applications | Drinking water, sewage, drainage, irrigation, industrial non-corrosive fluids | Water supply, industrial pipelines, high-pressure systems |

Advantages of UPVC Pipes

-

Corrosion-Free Water Flow: Unlike GI pipes, UPVC pipe for water supply does not corrode or form rust deposits, ensuring cleaner water, better taste, and healthier consumption over time.

-

Long-Term Durability: UPVC pipelines have a service life of 25–50 years, far exceeding GI pipes, even in areas with acidic or hard water, reducing the frequency of replacements and associated costs.

-

Easy Installation and Flexible Design: UPVC pipework allows for easy cutting, joining, and customization with UPVC pipe fittings, u PVC fittings, and solvent cement, enabling plumbers to design complex water distribution systems without specialized tools.

-

Cost-Effective: While the initial investment in UPVC pipes might sometimes be slightly higher than GI, the long-term savings on maintenance, repairs, and replacements make it more economical.

-

Lightweight and Safe: Handling white UPVC pipe or grey UPVC pipe is significantly easier than GI, reducing labor costs, installation time, and the risk of injuries or pipe damage during construction.

-

Versatile Applications: UPVC pipes are suitable for potable water supply, sewerage systems, rainwater harvesting, and even certain industrial fluid transfer applications, making them highly versatile in construction and infrastructure projects.

Scotto Pipes is a leading manufacturer and supplier of high-quality piping solutions, specializing in UPVC pipes, PVC pipes, garden pipes, and suction pipes. Known for their durable and corrosion-resistant products, Scotto Pipes caters to a wide range of applications, including water supply, drainage, industrial fluid transfer, and irrigation systems. With a focus on precision engineering, reliability, and adherence to international quality standards, Scotto Pipes ensures long-lasting performance and efficient installation, making them a trusted choice for residential, commercial, and industrial projects.

Limitations of GI Pipes

While GI pipes have certain advantages, particularly in mechanical strength, they are increasingly being replaced by UPVC pipes in modern water supply systems. The main limitations include:

-

Internal Corrosion: Constant water flow, especially hard water, leads to scaling and rust formation inside GI pipes, reducing flow efficiency and water quality.

-

Heavy Weight and Complex Installation: GI pipes are cumbersome, require additional labor, threading machines, and welding, which increases construction time and costs.

-

High Maintenance Costs: Frequent inspections, cleaning, and repainting are required to prevent rust, adding to overall lifetime expenses.

-

Water Quality Issues: Over time, corroded GI pipes can release metal particles and zinc into water, which may affect taste and pose health risks if consumed.

Pipe Installation Considerations

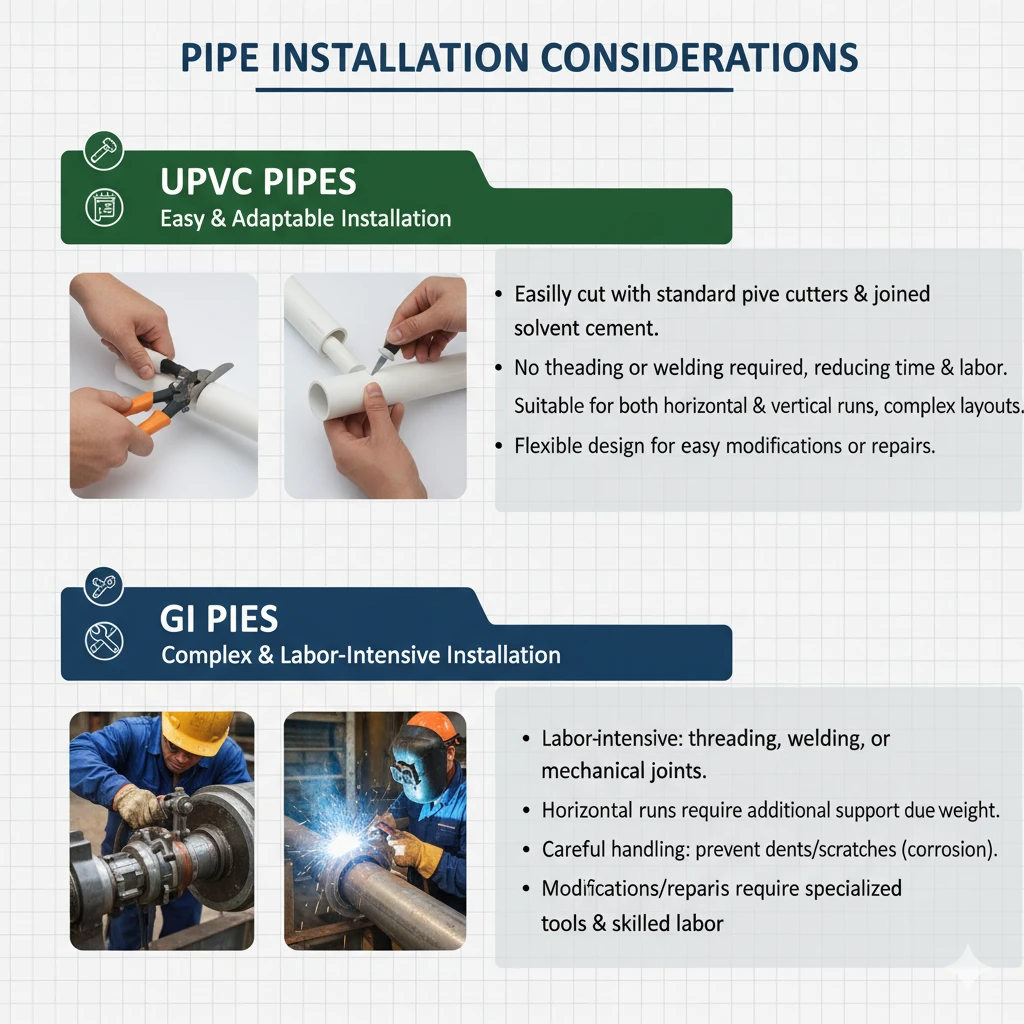

UPVC Pipes:

-

Can be easily cut using standard pipe cutters and joined using solvent cement or mechanical UPVC fittings.

-

No threading or welding required, reducing installation time and labor costs.

-

Suitable for both horizontal and vertical runs, including complex plumbing layouts.

-

Flexible design allows modifications or repairs without dismantling large sections.

GI Pipes:

-

Installation is more labor-intensive due to the need for threading, welding, or mechanical joints.

-

Horizontal runs require additional support due to weight, increasing complexity and cost.

-

Careful handling is necessary to prevent dents or scratches that accelerate corrosion.

-

Modifications or repairs are more complicated and require specialized tools and skilled labor.

Cost Analysis: UPVC vs GI Pipes

UPVC Pipes:

-

Low initial cost in most regions, with competitive pricing for standard diameters like 1 inch UPVC pipe.

-

Minimal maintenance costs due to corrosion resistance, saving money over decades.

-

Long service life ensures better ROI and fewer replacements, making it ideal for residential and commercial projects.

GI Pipes:

-

Higher material cost due to steel composition and galvanization process.

-

Skilled labor required for installation increases the overall project cost.

-

Periodic maintenance, painting, and eventual replacement make GI pipes more expensive over the long term.

Common Questions About UPVC and GI Pipes

1. Are UPVC Pipes Suitable for Hot Water Supply?

Yes, UPVC pipework can handle water temperatures up to 60°C safely. For extremely hot water systems, CPVC or metal pipes are recommended, but UPVC works well for typical household applications.

2. Can GI Pipes Carry Drinking Water Safely?

While GI pipes can transport drinking water initially, prolonged use can lead to rust and scaling inside the pipe, affecting taste and safety. UPVC pipes and fittings remain the safer and more reliable option.

3. How Long Do UPVC Pipelines Last?

Properly installed and maintained UPVC pipelines can last 25–50 years, whereas GI pipes generally last 15–30 years depending on water quality, environment, and usage.

4. What Size UPVC Pipe Should I Choose?

For household water supply, a 1 inch UPVC pipe is common, but larger diameters may be needed for multi-story buildings or commercial projects. Proper sizing ensures optimal water pressure and flow.

Conclusion: Which Pipe Is the Best Choice?

For modern water supply systems, UPVC pipes clearly surpass GI pipes in durability, safety, cost-effectiveness, and ease of installation. While GI pipes still have applications in high-pressure industrial setups, UPVC pipes provide a long-lasting, low-maintenance, and environmentally friendly solution for most residential and commercial plumbing needs.

Investing in high-quality UPVC pipework and reliable UPVC fittings ensures cleaner water, fewer repairs, and a sustainable plumbing system that can last decades, making UPVC the preferred choice for modern infrastructure.