Industrial and agricultural use of pipe depends on selection of the right kind of pipe if durability, performance and efficiency are to be achieved. Two common types of pipes available are Suction Pipes and Rubber Pipes. They have different advantages but the best one is Suction when it comes to functionality, durability, indoor usage and other aspects, the Suction Pipe is often preferred over the rest. In this blog, I will discuss features, advantages, and disadvantages between Suction Pipe and Rubber Pipe, and then how the Suction Pipe is the winner for many industries.

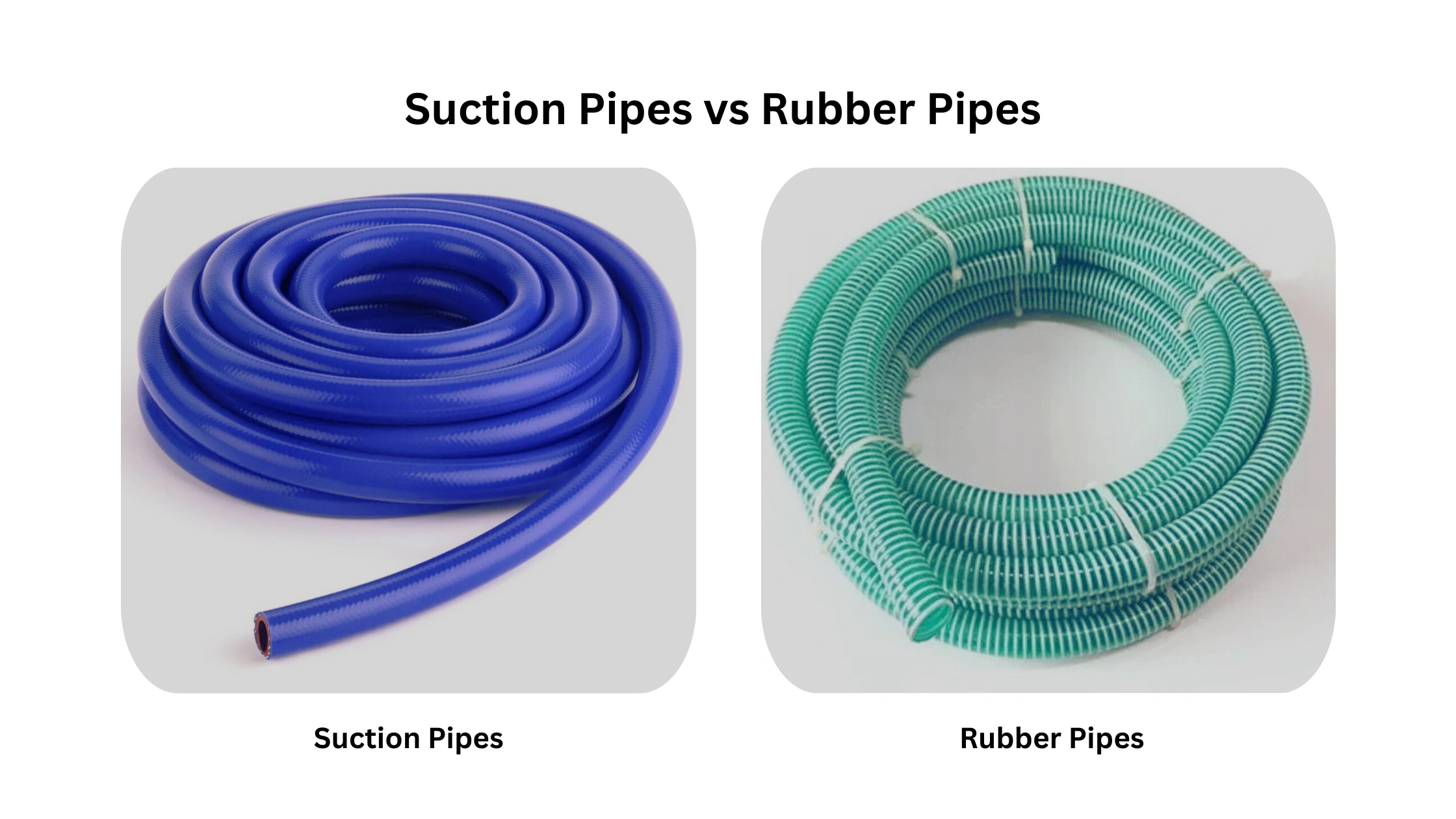

What Is a Suction Pipe?

A Suction Pipe is designed for use under suction fluid conditions. Since it is used in applications where liquids or slurries need to be taken from a source as well as pumped to another location, primarily in water pumping, agricultural irrigation, and industrial fluid transfer, it is widely used. To withstand the vacuum pressure that is created during suction, the suction pipes are also reinforced so that the suction liquid flows without a risk of the collapse of the suction pipe under the suction force.

We at Scoto Pipes provide a wide variety of Suction Pipes that are of high performance, durability and flexibility and these are perfect for different industrial and agricultural purposes.

What Is a Rubber Pipe?

Flexible and elastic tubes of high quality rubber material are called Rubber Pipes. This is used both in domestic as well as industrial applications while they are used to transport the gases, liquids and other substances. It is known that rubber pipes bend and wear resistance. However, these pipes can also handle the high temperatures as well as offer a good resistance to chemicals, but are not always the best choice in every application because these pipes do not have the best resistance tolerance pressure.

Suction Pipes vs Rubber Pipes

Below are some comparison factors made between Suction Pipes and Rubber Pipes, which will help you to understand a little bit better which one is best suited to your needs.

1. Pressure and Suction Resistance

Suction Pipe: Suction pipes are specially crafted to withstand the negative pressure (suction). The vacuum pressure created when sucking liquid through the pipe is rendered safe with the help of a multitude of materials such as steel wires or fabric layers. This makes suction pipes attractive for use in pump and drainage systems as well as for drawing liquids from a source.

Rubber Pipe: Rubber pipes being flexible and durable are not as resistant to the negative pressure produced in suction applications. Even rubber pipes can stand some pressure, but rubber pipes are usually used in situations of low pressure and to transport fluids generally. However, it does not perform as well when high pressure suction applications are required.

Winner: Suction Pipe – due to its ability to handle high suction pressure without collapsing.

2. Durability and Strength

Suction Pipe: Suction pipe is reinforced in order to last. They’re prepared to take the abuse, abrasion, and harsh environmental conditions. In addition, they are also resistant to UV rays, ozone, weathering, and they do a good job over extended periods of time, even when exposed to outdoor environments.

Rubber Pipe: Flexible and durable but more susceptible to wear when subjected to external effects, such as UV rays, extreme temperatures and physical stress, rubber pipe is the likely choice for those needs. Rubber pipes can degrade with time, specifically if used outdoors without protection.

Winner: Suction Pipe – due to its ability to handle high suction pressure without collapsing.

3. Flexibility and Handling

Suction Pipe: Suction pipes are generally flexible, which allow them to be coiled, transported and stored easily. They are less flexible than rubber pipes, especially in some of the pressure conditions. But it can hound their use in some very flexible applications.

Rubber pipes: Rubber pipes are known to have the greatest flexibility. Thanks to their ability to bend and twist without consequence to themselves, they offer perfect flexibility, predictive maintenance, as can be repeatedly moved for installation in places that are not easy to access. However, this flexibility is beneficial when setup and change of direction are required quickly.

Winner: Rubber Pipe – for its superior flexibility and ease of handling.

4. Temperature and Chemical Resistance

Suction Pipe: Suction pipes are suitable for industrial applications where chemicals come into contact, and they are able to work at a wide range of temperature and are resistant to many chemicals. Suction pipes are very strong and therefore are ideal in that sense to use in various environments such as agricultural environments, wastewater systems and more.

Rubber Pipe: Rubber pipes are good in resisting the change of temperature but are not good at handling extreme conditions especially in pressure change. Additionally, the material can also exhibit limited resistance to some chemicals particularly oils, fuels and strong acids that can degrade the material overtime.

Winner: Suction Pipe – due to its ability to resist a wider range of temperatures and chemicals.

5. Cost

Suction Pipe: suction pipes are more expensive than discharge pipes, due to the reinforced material and the special design needed for suction conditions, only fiberglass, ceramic, and masonry pipes are usually supplied under suction conditions. But many times, the up front cost to make suction pipes is high, but long term durability and performance warrant it.

Rubber Pipe: Rubber pipes are cheaper than the suction pipes. However, at high stress they may still not be as durable and in demanding applications more frequent replacements and higher long term costs may be incurred.

Winner: Rubber Pipe – for lower initial costs, though suction pipes offer better value in the long run for high-demand applications.

Key Differences Between Suction Pipes and Rubber Pipes

| Feature | Suction Pipes | Rubber Pipes |

| Material | Typically made from PVC or reinforced materials, offering durability and pressure resistance. | Made from natural or synthetic rubber, offering flexibility and resilience. |

| Pressure Resistance | Designed to handle high suction pressures and negative pressure. | Less effective in handling high suction or negative pressure. |

| Durability | Highly durable, resistant to abrasion, chemicals, and UV exposure. | Can degrade over time with UV light, ozone, and harsh chemicals. |

| Flexibility | Moderate flexibility, ideal for stable flow but less maneuverable. | Highly flexible, ideal for applications requiring bends and movement. |

| Applications | Best for water pumps, industrial machinery, and suction-based systems. | Suitable for fluid transfer in low-pressure systems, automotive, and air transfer. |

| Cost | Generally more expensive due to reinforced construction. | Typically less expensive upfront but may require more maintenance. |

| Maintenance | Low maintenance due to strong resistance to wear and tear. | May require more frequent maintenance or replacement due to material degradation. |

| Storage and Handling | More rigid, can be harder to store in tight spaces compared to rubber pipes. | Easy to store and handle, especially in confined spaces due to its flexibility. |

| Longevity | Long lifespan due to robust construction. | Shorter lifespan compared to suction pipes, especially under harsh conditions. |

| Use in High-Pressure Systems | Ideal for high-pressure applications, including suction and discharge systems. | Not recommended for high-pressure or suction applications. |

Why Choose Suction Pipe Over Rubber Pipe?

While rubber pipes are certainly valuable for many applications, Suction Pipes win out in most scenarios, especially when it comes to suction applications. As they can withstand high negative pressure and environmental damage, they are easy to use for industries like agriculture, water treatment, and industrial fluid handling, because they provide reliable fluid transport in the presence of various challenges.

Key Benefits of Suction Pipes:

-

High Pressure Resistance: Suction pipe has a high pressure resistance, it can be sucked under negative pressure without collapsing, so it can operate in a smooth way in the pumping and drainage system.

-

Durability: Reinforced construction will extend the life of suction pipes in harsh outdoor conditions.

-

Versatility: Wide range of applicability: Suction pipes can be applied to a wide variety of uses, ranging from pumping water, irrigation, fluid transport.

-

Chemical Resistance: Suction pipes are more resistant to chemicals and harsh materials.

Choose the Right Suction Pipe!

Conclusion

The Suction Pipe is often the best pipe to select if choosing the right pipe based on strength, durability and the ability to handle high pressure suction applications. Scoto Pipes provides you with top quality Suction Pipes that can be used irrespective of whether you need to transfer liquids in an agricultural or industrial environment.

Scoto Pipes Suction Pipes has more information about our range and the best suited suction pipes for your needs.