Polyvinyl chloride (PVC) pipes are very common materials largely used in plumbing, industrial, and construction applications because of its diversity, durability, and cost effectiveness. It’s a complete guide below which includes their specifications, applications, and benefits.

What Are PVC Pipes?

Polyvinyl chloride, or PVC, is a synthetic polymer that is rigid and resistant to chemicals. It becomes flexible and suitable for a range of uses when mixed with additives such as plasticizers. For more than 80 years, PVC pipes have been the standard choice for industrial plumbing, sewage networks, and water supply systems all over the world.

Types of PVC Pipes

PVC pipes come in different types, each suited for specific applications:

• Chlorinated PVC (CPVC): For use with hot water lines due to ability to withstand higher temperatures.

• Flexible PVC: PVC used in tight spaces or required to be flexible.

• Standard PVC Pipes: These are used in primary plumbing systems.

• Pressure-Rated PVC Pipes: Designed for high-pressure water systems.

• Foam-Core PVC Pipes: Used for pipes within direct pressure applications such as water systems.

• Chlorinated PVC (CPVC): Engineered PVC Pipes for Chemical Transport and Heavy Duty Use

Key Advantages of PVC Pipes

Here are the key advantages of PVC (Polyvinyl Chloride) pipes:

• Corrosion/Weathering/Chemical: Corrosion, weathering, and chemical resistant.

• Lightweight: Not heavy like metal pipes.

• Low Maintenance: Requires minimal upkeep due to its non-corrosive nature.

• Affordable: Pricey alternative to metal or ceramic.

• Low Coefficient of Friction: Low coefficient of friction is the reason why water flows with good characteristics.

• Versatility: Used in different configurations with fittings such as bends, valves and clips.

How Are PVC Pipes Manufactured?

The process of production includes several steps to ensure quality and reliability:

• PVC Resin Preparation: It (PVCR) is blended with stabilizers, plasticizers and colorants to give it some desired properties.

• Molten state production: the mixture is heated to the molten state and forced through a die to form a pipe.

• Shaping: The shaped pipe is shaped into its form by cooling it with water or air.

• Flopping: Pipes are flopped for laying on the ground and side rolling.

• Socketing: One end of the pipe could be pulled out into a bell shaped plug for easy connection.

• Testing: Before each batch is shipped, all dimensions, wall thicknesses and material integrity are tested; meeting industry standards to ensure quality control.

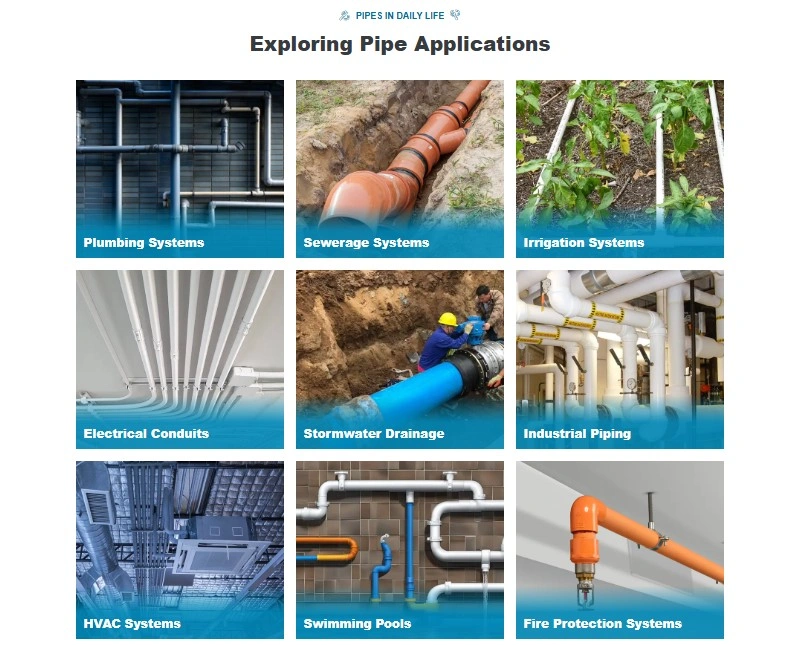

Applications of PVC Pipes

1. Plumbing

PVC pipes are so cheap and easy to install, they are used ubiquitously in all residential and commercial plumbing systems. Ideal for water supply lines and drainage systems.

2. Sewage Systems

Wastewater evacuation systems usually use PVC pipes due to their ability to resist chemical reaction and corrosion with time. They are also used as rainwater drainage from roofs.

3. Industrial Applications

PVC pipes are used by industries to transport hazardous chemicals, to cool water systems, to process, etc., as they are robust and resistant to harsh environments.

4. Agricultural Irrigation

Agriculture uses PVC pipes widely in irrigation system as it saves water than open channels and can even be placed on difficult terrains.

5. HVAC Systems

The ductwork system is used for heating, ventilation, and air conditioning using PVC pipes. The hot water is handled efficiently by CPVC variants.

6. Electrical Conduits

Insulation of electric wires and wiring systems are protected from environmental damage by using PVC.

PVC Pipe Maintenance Tips

Avoid UV Exposure: Wrap or Paint Outdoor Pipes

Flush Periodically: Prevent buildup of minerals or clogs.

In Cold Climates: Surround product with foam sleeve to prevent freezing.

Inspect for Leaks: Every season, inspect joints and connectors

Conclusion

PVC pipes are a versatile, durable, and cost-effective solution for various infrastructure needs. Their widespread use across industries such as plumbing, agriculture, and HVAC demonstrates their adaptability and reliability. With proper selection based on application requirements, PVC remains a top choice globally for piping systems.

At Scotto Pipes, we take pride in delivering a wide range of premium-quality PVC piping solutions designed to meet diverse application needs.

FAQs

1. Can PVC pipes be used for drinking water?

Yes, Schedule 40 PVC is safe for cold drinking water but not for hot water. CPVC is preferred for hot water lines.

2. Are PVC pipes recyclable?

Technically, yes. However, recycling PVC is less common due to contamination and separation challenges.

3. Can a PVC pipe freeze and burst?

Yes. In freezing temperatures, uninsulated PVC may crack or burst due to expanding water.

4. What’s the lifespan of PVC pipes?

Properly installed, they can last 50–100 years depending on the application and exposure.

5. How do I join PVC pipes without leaks?

Clean, prime, and cement each joint carefully. Allow time for curing based on temperature and humidity.

6. Are PVC pipes better than metal?

They are more corrosion-resistant and cheaper, but metal pipes may be better in high-pressure or high-temperature environments.