Choosing the right size of a pipe in your project may appear a small matter, but it is a highly important process in the safety, operation or efficiency as well as the economy of any piping arrangement. If you are installing a pipe in a commercial or a residential upgrade, choosing the right pipe diameter & thickness of the pipe can affect everything including water flow, and maintenance effort.

This step-by-step tutorial will explain the basics of sizing pipes and assist you in making the right decision depending on your particular application.

What Does a Pipe Diameter Rally Mean?

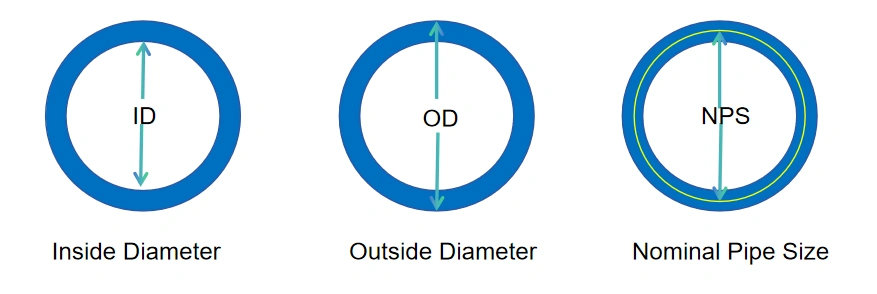

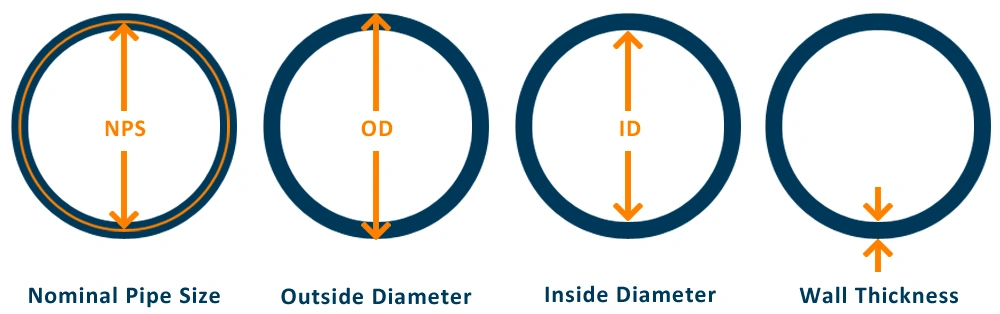

Talking about right pipe diameter we usually talk about the Nominal Pipe Size (NPS). This is a standard dimension which is not always an accurate representation of the internal or external diameter of the piping. For example, a 1-inch NPS pipe may have an actual outside diameter of 1.315 inches. Understanding this difference is crucial, especially when fittings or flow calculations are involved.

Key Takeaways

-

Internal Diameter affects the fluid flow rate

-

External Diameter matters for fitment in tight spaces

-

Always double-check whether specs mention NPS or actual measurements

What Does a Pipe Thickness Rally Mean?

The Pipe wall thickness, commonly known as pipe schedule or SCH, contains information about the pressure capacity of the pipe. A pipe having a thicker wall (such as Schedule 80) will support greater pressure as well as being heavier and more costly than a thin wall (such as Schedule 40). For example, Schedule 40 and Schedule 80 are common for PVC, CPVC, and UPVC pipes:

-

Schedule 40 pipes are commonly used in residential plumbing.

-

Schedule 80 pipe is often found in industrial applications due to higher strength.

Piping Schedule Chart (in mm)

Choosing the right pipe wall thickness is crucial for pressure handling and durability. Below is a quick guide to Schedule 40 pipe thickness in mm and Schedule 80 pipe thickness in mm for common pipe sizes.

| NPS | OD (mm) | SCH 40 Thickness (mm) | SCH 80 Thickness (mm) |

| 15 (½") | 21.3 | 2.77 | 3.73 |

| 20 (¾") | 26.7 | 2.87 | 3.91 |

| 25 (1") | 33.4 | 3.38 | 4.55 |

| 32 (1¼") | 42.2 | 3.56 | 4.85 |

| 40 (1½") | 48.3 | 3.68 | 5.08 |

| 50 (2") | 60.3 | 3.91 | 5.54 |

| 80 (3") | 88.9 | 5.49 | 7.62 |

| 100 (4") | 114.3 | 6.02 | 8.56 |

Why Is Pipe Diameter Important?

Provides Proper Water Flow: The diameter will ensure how much water flows through at a particular time. A smaller pipe will result in the low pressure and insufficient supply, whereas a larger pipe will result in unnecessary cost and difficulties during installation.

Minimizes Pressure Loss: Small pipes increase friction losses which cause more pressure losses in long lengths of pipe. These losses are reduced by proper sizing which ensures constant water delivery.

Avoids Pipe Damage: Improper sizes may overwork the wall of the pipe leading to the possibility of leaks or pipe bursts.

Why Is Pipe Wall Thickness Important?

Pressure Rating: Thicker walls experience greater internal pressure and can thus be used in high-rise or in industrial systems.

Durability: Thicker pipes are less liable to breakage or injuring by external forces or corrosion.

Compliance: Some applications (e.g. underground or exposed piping) have a minimum wall thickness as specified by code.

Standard Pipe Diameters: Residential vs. Commercial

Residential Pipe Diameters

| Application | Common Pipe Material | Standard Diameter (mm) |

| Water Supply (Internal) | CPVC / PEX / GI | 15 - 25 |

| Main Water Line (Inlet) | PVC / GI / HDPE | 25 - 40 |

| Garden/Outdoor Supply | PVC / HDPE | 20 - 32 |

| Drainage (Wastewater) | PVC (SWR) | 40 - 75 |

| Soil & Vent Pipe | PVC (SWR) | 75 - 110 |

| Rainwater Downpipes | PVC | 75 - 110 |

Commercial Pipe Diameters

| Application | Common Pipe Material | Standard Diameter (mm) |

| Main Water Supply | GI / HDPE / PVC | 50 - 90 |

| HVAC (Chilled Water/Cooling) | MS / HDPE / PPR | 50 - 160 |

| Fire Fighting (Sprinklers) | GI / MS / HDPE | 25 - 100 |

| Drainage & Sewer | uPVC / RCC | 110 - 315 |

| Industrial Waste Disposal | HDPE / uPVC | 75 - 200 |

| Roof/Rainwater Drainage | uPVC / HDPE | 110 - 200 |

Always verify with local codes and specific manufacturer recommendations for your application.

Standard Pipe Thickness: Residential vs. Commercial

Residential Pipe Thickness Chart (in mm)

| Pipe Material | Common Diameter (mm) | Wall Thickness (mm) | Usage & Remarks |

| CPVC (SCH 40) | 15 – 25 | 1.7 – 2.8 | Hot & cold water supply |

| PVC (Class 2–6) | 20 – 50 | 1.2 – 2.7 | Cold & low-pressure systems |

| uPVC (SWR/Pressure) | 40 – 110 | 1.8 – 3.2 | Waste, rainwater drainage |

| GI (Light Class A) | 15 – 25 | 2.0 – 2.6 | Indoor water piping |

| PEX (Flexible) | 15 – 25 | 1.5 – 2.2 | Internal water lines |

| HDPE (SDR 11–17) | 20 – 50 | 1.8 – 4.5 | Underground supply |

| Suction Pipe (PVC Spiral) | 25 – 50 | 2.0 – 3.5 | Water pumps, irrigation |

| Garden Pipe (Flexible PVC) | 13 – 25 | 1.0 – 2.0 | Gardening, washing, home water |

Commercial Pipe Thickness Chart (in mm)

| Pipe Material | Common Diameter (mm) | Wall Thickness (mm) | Usage & Remarks |

| GI (Medium/Heavy Class) | 25 – 100 | 2.6 – 5.4 | Heavy water use |

| MS (SCH 40/80) | 25 – 150 | 3.2 – 8.0 | HVAC, industrial piping |

| HDPE (SDR 11/13.6 /17) | 63 – 160 | 5.8 – 14.6 | Gas & effluent systems |

| uPVC (Class 1 to 6/SWR) | 75 – 160 | 2.0 – 4.5 | Drainage & pressure water |

| Suction Pipe (Heavy Duty PVC Spiral) | 50 – 150 | 3.0 – 6.5 | Dewatering, pump suction lines |

| SS (SCH 10/40) | 25 – 100 | 1.5 – 6.0 | Food, pharma, or chemical piping |

| Garden Pipe (Flexible PVC) | 19 – 32 | 1.2 – 2.5 | Landscapes, commercial washing |

Key Factors in Selecting Pipe Thickness & Diameter

Choosing the proper pipe sizes and pipe thickness depends on multiple technical and environmental factors:

-

Fluid Type: High viscosity fluids, corrosive or abrasive fluids might need bigger diameters, thicker walls to carry them safely and minimize erosion.

-

Operating Pressure: High-pressure systems require thicker pipes to avoid bursting or other damages. Pressure loss may be enhanced with smaller diameters.

-

Flow Rate Requirements: The inside diameter should enable the required gallons per minute or liters per second without loss in the pressure.

-

Temperature Range: Hot liquids need thicker walls or other material to prevent deforming or bursting.

-

Location of Installation: Pipes that are laid in the ground or are directly exposed to sun may require extra protection or strength.

-

Material of the Pipe: Copper, PVC, or Steel, or PEX, all perform differently in pressure and temperature.

-

System Design & Layout: Piping runs of a longer length, bends, or changes in elevation will need to be sized in a manner that ensures that flow and pressures are not compromised.

-

Code Compliance: Use local building codes, and industry (such as ASME, ASTM) standards when there are published minimum sizing and certain pipe wall thickness standards.

How to Calculate the Right Pipe Size

1. Fixture Unit (FU) Method

-

Assign FU values to each fixture (sink, toilet, shower, etc.).

-

Add up total FUs for each branch or main line.

-

Use plumbing charts to match FU totals to pipe diameters.

2. Velocity Method

-

Decide on a safe water velocity (typically 3–8 feet/second).

-

Flow Rate (GPM)=Pipe Area (sq. in.)×Velocity (ft/sec)

-

Flow Rate (GPM)=Pipe Area (sq. in.)×Velocity (ft/sec)

-

Rearrange to solve for pipe diameter.

3. Pressure Drop Method

-

Set an acceptable pressure drop (e.g., 2 psi per 100 feet).

-

Use sizing charts or software, factoring in pipe length, material, and number of fittings.

Tips for Choosing Pipe Diameter & Thickness

Consult Sizing Charts: Use manufacturer or international plumbing code charts for your specific pipe material.

Consider Future Expansion: If you plan to add fixtures or increase usage, pipes size accordingly.

Account for Pipe Length and Elevation: Longer runs and higher elevations may require larger diameters to maintain pressure.

Professional Advice: For complex systems or commercial projects, consult a licensed plumber or engineer.

Conclusion

Choosing the appropriate pipe diameter and wall thickness is essential for ensuring durability, efficiency, and safety in any plumbing or piping system. Use tools like a piping schedule chart and consult professionals for accurate sizing based on PVC pipe dimensions, pipe schedules, and pipe sizes. By understanding how factors like water flow, pressure, temperature, and material compatibility influence sizing, you can make informed decisions that support both performance and longevity.

Whether it’s for a residential upgrade or a large-scale commercial project, referencing standard sizing charts and consulting professionals when needed will help you select the right pipe for the job—with confidence. Scotto Pipes as a trusted manufacturer and supplier of high-quality UPVC, PVC, suction pipes, garden pipes, we offer:

-

A complete range of standard and custom sizes.

-

Products manufactured to global quality standards.

-

Technical support to help you choose exactly what you need.