Suction pipes are a necessary part of fluid transportation systems, being used to obtain liquids or slurry from one place to another. Industries, which include agriculture, construction, manufacturing, etc. use them. We should know whether we will be using the suction pipe for irrigation, dewatering, or industrial purposes, as we need to ensure that it matches our needs.

This comprehensive guide will include applications, types, materials, advantages, maintenance and more about suction pipes, and a leading manufacturer in the industry.

What Are Suction Pipes?

The suction pipe is a specially made pipe built to allow for liquid, gas or slurry to be pulled through around a pump system by the use of a vacuum. Unlike standard pipes, suction pipes must not collapse under negative pressure. Usually, they are reinforced with flexible or rigid materials to improve durability and performance.

Importantly, these are water supply systems, industrial fluid transfer and even medical devices. The efficiency of the pipe handling various kinds of liquids such as water, chemicals, oil and sludge is dependent on the material and structure of the pipe.

Uses of Suction Pipes

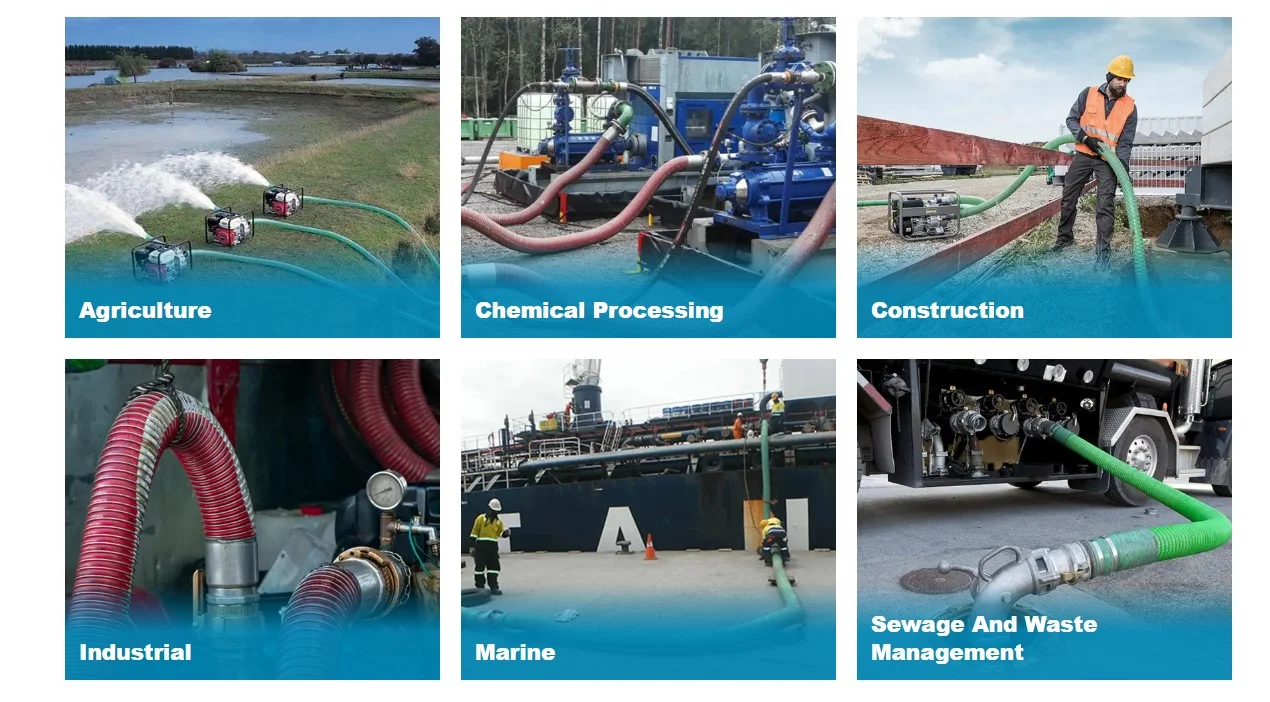

Suction pipes are highly versatile and are used across various industries. Below are some common applications:

1. Agriculture and Irrigation

Irrigation and water transfer are being used widely in agriculture as they are using suction pipes. This gives them a hand in pumping water from rivers, wells, and reservoirs to fields. These instruments are important for farmers as they can use them to have a steady water supply for crops thereby relying less on rainfalls.

2. Construction and Dewatering

For instance, most construction sites need to employ dewatering systems that help in removal of water built up in place. In these processes, suction pipes are critical to efficient draining of water from excavation sites, foundations, and trenches thereby avoiding delays and rendering the works safe.

3. Industrial Fluid Transfer

This is because in industries like chemical manufacturing, food processing and pharmaceuticals, the liquids transported are solvents, oils, and chemicals that require transfer via suction pipes. These settings call for pipes that are resistant to corrosion and to chemical reactions for safety and efficiency.

4. Wastewater and Sewage Management

The wastewater and sewage are transported through suction pipes to the treatment facilities by municipalities and industries. Because of this, these pipes need to be durable and averse to clogging to guarantee a smooth run of waste management systems.

5. Marine and Dredging Applications

For dredging operations, such as ports, harbors and offshore drilling sites, suction pipes are used, to help alleviate sediments, silt and other underwater elements. The pipes are created to work under severe marine situations and high suction forces.

Types of Suction Pipes

Suction pipes come in various types, each designed for specific applications. Here are the most common types:

1. PVC Suction Pipes

When choosing (Polyvinyl Chloride) PVC suction pipes, that’s because they are lightweight and durable, and have high resistance to corrosion and chemical exposure. Affordability and easy handling make these pipes widely used in all sectors.

Common Applications:

-

Irrigation and Agriculture – Without PVC suction pipes, irrigation would not be possible as farmers need to rely on the same in order to draw water from wells, rivers and reservoirs to provide a constant source of water for crops. Also, the properties that make them UV resistant make them also suitable for outdoor applications.

-

Domestic Water Supply – They are used in domestic purposes: they draw the water from underground sources.

-

Chemical Fluid Transfer – As PVC is non-reacting, PVC pipes are the best to transfer chemicals, fertilizers and industrial fluids safely.

2. Rubber Suction Pipes

High flexibility, durability and resistance to rough environmental conditions are reasons of choosing rubber suction pipes. These are pipes made from synthetic or natural rubber of the highest grade and they can withstand extreme temperatures and pressures without losing their shape and strength.

Common Applications:

-

High-Pressure Suction Applications – These are used in manufacturing plants and processing industries where high suction and fluid transfer is required.

-

Chemical and Oil Transport – This rubber composition provides a strong, often chemical-resistant pipe for the transporting of liquids classified as hazardous as oils, fuels, and acids.

-

Water and Wastewater Management – Large consumption of rubber suction pipes is made by sewage treatment plants and drainage systems because they are nonclogging and wear-resistant.

3. Steel Suction Pipes

The strongest and most durable pipework material is of course steel suction and it is recommended either for high-pressure applications in heavy industrial environments or for in which the risk of vandalism is high. Generally, galvanized steel, stainless steel or carbon steel are used to make these pipes.

Common Applications:

-

Oil and Gas Industries – Used for suction and discharge of petroleum products, crude oil, and natural gas in refineries and pipelines.

-

Heavy duty Dredging operations – required in marine and mining industries where erosion of sediment, slurry and gravel needs to be transported quickly.

-

High-Pressure Applications - Steel Pipes and parts are recommended for firefighting, hydraulic operation, and industrial suction services in high-pressure situations.

4. Flexible Suction Hoses

Versatile and made of PVC, rubber, and reinforcing wire, for flexibility and strength, the flexible suction hoses can be used in various ways. These clean-out hoses are made to be lightweight and easy to manipulate which is good for many industrial and emergencies.

Common Applications:

-

Dewatering and Pumping Sites – Used in removing water from excavation sites and basements.

-

Firefighting Applications – They are essential in firefighting applications to rapidly pump and dump large volumes of water.

-

Industrial Payload – Capable of transporting a huge range of industrial payloads, including chemicals, sludge, slurry and many more.

Materials Used in Suction Pipes

The choice of material significantly impacts the durability and performance of suction pipes. The most common materials used include:

-

PVC (Polyvinyl Chloride): Lightweight, corrosion-resistant, and cost-effective.

-

Rubber: Highly flexible and resistant to abrasion and chemicals.

-

Steel: Strong and durable, ideal for high-pressure applications.

-

Reinforced Polyurethane: Offers excellent chemical resistance and flexibility.

Each material has its advantages, and selecting the right one depends on the specific application and environmental conditions.

Advantages of Suction Pipes

Suction pipes offer several benefits, making them indispensable in various industries. Here are some key advantages:

1. Durability and Longevity

Suction pipes have to be able to endure in most extreme conditions, but often with high pressures, chemical exposure, and temperature variation. In particular, steel and rubber suction pipes provide long service duration.

2. Flexibility for Easy Installation

The rubber and flexible hoses are very easy to handle and install even in such complex piping systems. They also are flexible enough to adapt to different layouts without losing performance.

3. Chemical and Corrosion Resistance

These are very resistant to chemicals, hence PVC and polyurethane suction pipes are suitable to transport corrosive substances. It ensures safety and also avoids pipe degradation with time.

4. Lightweight and Easy to Transport

The high loading of metal pipes to the different accessories for installation makes them heavier in weight compared to PVC and flexible hoses; hence they end up becoming more expensive in terms of transportation and installation. Therefore it is preferred for agricultural and construction applications.

5. High Suction Power and Efficiency

These suction pipes ensure that resilience is-good, enabling easy passage of fluid consumption and low energy. It helps optimize productivity in all the areas of the various industries.

Maintenance and Care Tips for Suction Pipes

To make sure the life and efficiency of the continuous suction system are maintained, proper maintenance, is required. Here are some essential tips:

-

Regular Inspection: Filters cracks, leaks or blockages in order to avoid performance issues.

-

Open Blockage Removal: Removes debris, sediments, or chemically related residues to retain smooth flow.

-

Usage of Dry, Shaded Area: Cheap pipes should be used in dry, shaded areas to prevent damage or degradation by UV of pipes material and prevent pipes damage.

-

Prevent Overload: Follow the suggested pressure and temperature limits to avoid repetitive wear.

-

Safely Maintaining: Replace old pipes to keep the operation and safety in good order.

Scotto Pipes: A Leading Suction Pipe Manufacturer and Supplier

When it comes to providing high quality suction pipes, Scotto Pipes is a trusted manufacturer and supplier. Scotto Pipes has years of experience in the piping business and has been able to make durable and reliable suction pipes of various necessities from ½ to 4 inches.

Why Choose Scotto Pipes?

-

High-Quality Materials – Scotto Pipes uses premium PVC, rubber, and reinforced material to stand for durability and work quality.

-

Wide Range of Products – They have a very wide range of products such as agricultural, construction, industrial, or marine.

-

Advanced Manufacturing Techniques –Their pipes are tested through drastic testing processes in manufacturing processes.

-

Customized Pipe Solutions – These provide customized pipe solutions according to industry requirements.

-

Global Supply Network – Scotto Pipes’ extensive distribution network provides for timely delivery to the global supply network.

Those seeking top-quality suction pipes for their businesses and as individuals can rely on Scotto Pipes as the best partner in the market in terms of efficiency, durability and innovation.

Conclusion

Fluid transportation across all industries is borne out by the suction pipe. You will need them for irrigation, industrial processing or wastewater management, choose the right type and material and you will be efficient and you will have longevity.

By choosing high-quality pipes from tested manufacturers like Scotto Pipes you can be sure of long-term savings and reliable performance. On top of the lifespan, proper maintenance still enhances the lifespan of these machines making it a smart investment for any industry. Looking for the best suction pipes? Contact Scotto Pipe today for premium-quality solutions!