Polyvinyl Chloride (PVC) and Unplasticized Polyvinyl Chloride (uPVC) are such commonly used materials, which have their important advantages and usage. Although they both share a common origin, these two materials do differ in terms of performance and characteristics; thus, each material has its application to specific functions.

Whether you have been at a loss as to which material you should use between PVC and uPVC or rather uPVC against PVC, the differences in the chemical composition of both products, durability of each product, environmental impact and application in diverse industries are explained in this guide. By the end of this post, you’ll understand which material is best suited for your needs, especially when evaluating the difference between PVC & uPVC for construction or industrial use.

What Is PVC Pipe?

PVC (Polyvinyl Chloride) pipe is an inorganic polymer or synthetic plastic material, namely the result of the levelling of vinyl chloride monomers to form a polymer. It is a very versatile plastic in the world which is usually used either rigidly or flexibly. It has a vast range of application with polyvinyl chloride pipes to flexible fittings.

Key Properties of PVC

-

Flexibility: Plasticizers are added to make PVC soft and pliable.

-

Lightweight: PVC is easy to handle and install.

-

Weather Resistance: It withstands exposure to moisture and UV rays.

-

Chemical Resistance: PVC shows high resistance to acids and alkalis, making it useful in industrial environments.

Common Applications of PVC

-

Pipes and Fittings: Flexible PVC is used for residential and commercial plumbing. Common options include PVC pipeline, plastic PVC pipe, PVC pipe fittings, and 1/1 2 PVC pipe used for water supply and drainage.

-

Electrical Insulation: PVC’s insulating properties make it ideal for wire coatings.

-

Medical Devices: Flexible PVC finds application in blood bags and medical tubing.

-

Construction Materials: Used for flooring, wall coverings, and ceilings.

What is uPVC Pipe?

Unplasticized Polyvinyl Chloride or uPVC pipe is a stiff form of PVC and does not contain any added plasticizers; therefore, it is unplasticized. This substance retains its rigid form as well as has numerous performance advantages that make it stand out when compared to ordinary PVC.

Key Properties of uPVC

-

Rigidity: uPVC is stronger and more durable than flexible PVC.

-

Non-Toxic: Since it is free from plasticizers, uPVC pipe is safe for applications involving drinking water.

-

Corrosion Resistance: It does not react with water, chemicals, or fluctuating temperatures.

-

Thermal Insulation: Its structure reduces indoor heat transfer, improving energy efficiency.

Common Applications of uPVC

-

Windows and Doors: uPVC frames provide excellent insulation in residential and commercial buildings.

-

Underground Piping: Durable enough to withstand burial and high pressures, uPVC pipeline solutions are preferred in infrastructure.

-

Drainage Systems: Resistant to sewage chemicals and corrosion, including use as PVC drain pipe replacements.

-

Cladding: Used on building facades for weather protection and aesthetics.

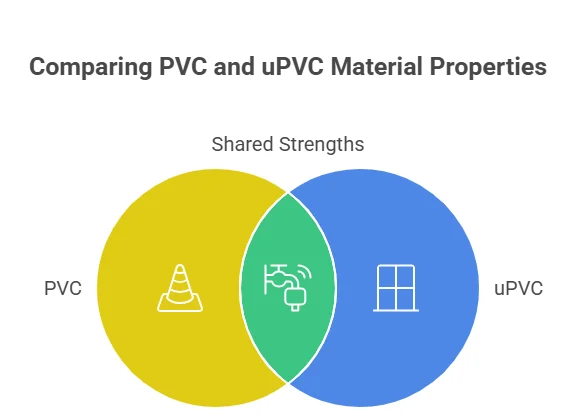

Key Differences Between PVC and uPVC

To understand which material works best for a particular need, it's essential to compare their properties and applications side by side. If you're researching the difference PVC and uPVC for a project, consider the following:

1. Chemical Composition

The fundamental difference lies in their chemical formulation.

-

PVC contains added plasticizers, making it softer and more flexible.

-

uPVC does not include these softening agents, which results in its rigidity and stronger structural performance.

2. Flexibility & Strength

-

PVC is suitable for flexible applications, such as hoses, wiring, and medical tubing, where pliability is necessary.

-

uPVC, by contrast, offers exceptional strength and is preferred for construction. For example, uPVC pipes are often buried underground without concerns of deformation.

3. Durability

The two materials are commonly associated with durability, though uPVC has the advantage when it comes to environments that need to be rigid and withstand more pressure. PVC is strong but may not have a long life when put under continual pressure or high temperatures.

Property Comparisons: PVC vs uPVC

| Property | PVC | uPVC |

|---|---|---|

| Tensile Strength | 20-25 MPa | 50-55 MPa |

| Flexural Strength | 40-80 MPa | 80-120 MPa |

| Impact Resistance | Good | Excellent |

| Hardness (Shore D) | 65-75 | 80-85 |

| Service Life | 20-40 years | 50-100 years |

4. Resistance to External Factors

-

UV and Weather: Both PVC and uPVC have very good resistance to sunlight and weathering, but the uPVC rigid form gives it superiority over PVC in long-term use outdoors, such as windows and doors.

-

Chemicals: The two materials are resistive to acids and alkaline chemicals and therefore can be used in plumbing and drainage. These strengths highlight the uPVC and PVC difference in practical usage.

5. Environmental Impact

From a sustainability perspective:

-

PVC has limitations due to the presence of plasticizers and additives, which can make recycling more complex and reduce its eco-friendliness.

-

uPVC, on the other hand, is often considered a more sustainable option. It is recyclable, durable, and non-toxic, which minimizes its environmental footprint over time.

6. Ease of Installation

-

PVC is light and flexible and hence is easier to carry and fit in tight places.

-

uPVC pipe is a little heavier owing to its rigidity; most of the designs of PVC are pre-fabricated, making it very easy to install, especially in a construction project.

7. Cost

The price of PVC is lower than that of uPVC, but it could have more associated costs in the long run compared to rigid materials, such as uPVC. The uPVC material may also be cheaper in the long run in the course of application in cases where the application requires longevity. Such factors as the price of PVC pipe and uPVC pipe depend on the region and the specifications of the product.

Feature Comparison: PVC vs uPVC

| Feature | PVC | uPVC |

|---|---|---|

| Flexibility | Flexible, with plasticizers | Rigid, no plasticizers |

| Strength | Less durable under high pressure | High strength and durability |

| Applications | Hoses, wires, medical tubing | Windows, doors, plumbing systems |

| Weather Resistance | Good | Excellent |

| Recyclability | Moderate | High |

| Cost | Lower upfront cost | Higher upfront, but better value |

Property Comparisons: PVC vs uPVC

1. Chemical Resistance

PVC Chemical Performance:

-

Acids: Good resistance to weak acids

-

Alkalis: Moderate resistance to basic solutions

-

Organic solvents: Limited resistance, may soften

-

Degradation: Plasticizers can leach over time

uPVC Chemical Excellence:

-

Acids: Excellent resistance to strong acids

-

Alkalis: Superior performance with caustic solutions

-

Chemical stability: No plasticizer migration or leaching

-

Industrial chemicals: Handles aggressive chemicals safely

Real-World Impact: uPVC's superior chemical resistance makes it ideal for industrial applications, chemical processing, and water treatment facilities where PVC might degrade or contaminate processes. This distinction clarifies the difference between PVC & uPVC in chemical-heavy environments.

2. Temperature Performance

Operating Temperature Ranges:

-

PVC: -10°C to 60°C (14°F to 140°F)

-

uPVC: -40°C to 80°C (-40°F to 176°F)

Thermal Characteristics:

-

Expansion rates: uPVC has lower thermal expansion

-

Heat distortion: uPVC maintains shape at higher temperatures

-

Cold performance: uPVC remains impact-resistant in freezing conditions

-

Fire resistance: Both are self-extinguishing, but uPVC performs better

3. UV and Weather Resistance

Outdoor Performance:

-

PVC: Requires UV stabilizers, degrades in 5-15 years outdoors

-

uPVC: Excellent UV resistance, maintains properties for 25+ years

-

Color retention: uPVC superior for maintaining original appearance

-

Brittleness: PVC becomes brittle faster than uPVC under UV exposure

Application Differences

PVC Primary Applications

-

Electrical cables: Insulation and jacketing for wiring

-

Medical devices: Tubing, blood bags, and flexible medical equipment

-

Packaging: Food wraps, blister packs, and bottles

-

Flooring: Vinyl tiles and sheet flooring

-

Inflatable products: Pool liners, inflatable boats, and toys

Benefits of These Uses: PVC is a flexible material, and it is therefore well suited to areas that need flexibility, installation in small areas, and applications that require the products to be nimble in their ability to fit into different shapes, particularly in plastic pipe uses.

uPVC Primary Applications

-

Building construction: Window frames, doors, and siding

-

Plumbing systems: Water supply pipes, drainage systems, and fittings

-

Industrial piping: Chemical processing and water treatment plants

-

Electrical conduits: Underground and exposed electrical protection

-

Infrastructure: Bridge components and architectural elements

Installation and Handling Differences

PVC Installation Characteristics

Advantages:

-

Flexibility: Easy to route through tight spaces

-

Cutting: Simple tools required for modification

-

Joining: Various methods including solvent welding and mechanical fittings

-

Cold weather: Remains workable in moderate cold

Challenges:

-

Support requirements: More frequent support needed due to flexibility

-

Expansion: Higher thermal expansion requires more expansion joints

-

UV protection: Must be protected if exposed to sunlight

uPVC Installation Requirements

Professional Installation Benefits:

-

Structural integrity: Maintains shape under load

-

Precise fitting: Dimensional stability ensures proper connections

-

Fewer supports: Rigid structure requires less frequent support

-

Weather resistance: Can be installed in various weather conditions

Installation Considerations:

-

Cutting precision: Requires sharp, clean cuts for proper joints

-

Temperature sensitivity: More brittle in extreme cold during installation

-

Tool requirements: May need specialized tools for larger installations

-

Professional expertise: Complex systems benefit from experienced installers

Making the Right Choice: Selection Criteria

One of the major industrialists and suppliers of plastic pipes, including PVC and uPVC pipes, garden pipes, and suction pipes of different sizes, is Scotto Pipes. As a manufacturer of durable, high-quality pipes, Scotto Pipes has compatible options available with or without flexibility that ensure every usage, whether in the short or long term, is guaranteed.

Contact Reliable Pipe Supplier

Choose PVC When:

-

Flexibility is required: Applications needing bendability

-

Budget constraints: Lower initial cost is critical

-

Temporary installations: Short-term or replaceable systems

-

Easy installation: DIY projects or simple applications

-

Specialized applications: Medical, packaging, or consumer products

Choose uPVC When:

-

Durability is priority: Long-term, permanent installations

-

Chemical resistance needed: Industrial or aggressive environments

-

Structural integrity required: Load-bearing or pressure applications

-

Low maintenance desired: Minimal ongoing maintenance requirements

-

Energy efficiency important: Building envelope applications

-

Professional installation available: Complex systems with expert installation

Conclusion

Which to use or PVC or uPVC, will be determined based on what your needs are to be addressed, your budgetary allocation, and the level of performance you expect. PVC is perfect in flexibility, cheaper starting costs, and ease of installation, hence suited in electrical applications, medical equipment and most temporary structures.

uPVC offers a better lifecycle value in terms of its extreme durability, chemical properties and unattended maintenance needs. It is more expensive initially but has a longer service life, saving energy, and little maintenance, so it is the favorite in permanent mounting, construction works, and rough industrial conditions.

Knowing these basic differences will help you in choosing the best material that would suit the technical requirements of your project, budgetary considerations and even long-term performance expectations in relation to your project. Regardless of which may be preferred on flexibility and cost factors of PVC or on durability and chemical resistance of uPVC, both have been tried and tested and of course, when matched well with the application where they are used.