The plastic pipes are critical components of the current structure that can be used in many bankruptcies from construction to agriculture. Both of them have been widely used due to their flexibility, affordable prices and absence of wear-out. Plastic pipes are suitable for all kinds of usage, right from water distribution networks to the transportation of chemicals. In this comprehensive tutorial we take a look at the different types of plastic pipes and how they are used across the industry. In this article, various types of plastic pipes together with their properties have been discussed as well as the uses in various industries.

Common Types of Plastic Pipes

-

PVC (Polyvinyl Chloride) Pipes

-

UPVC (Unplasticized Polyvinyl Chloride) Pipes

-

CPVC (Chlorinated Polyvinyl Chloride) Pipes

-

HDPE (High-Density Polyethylene) Pipes

-

PEX (Cross-Linked Polyethylene) Pipes

-

PP (Polypropylene) Pipes

-

ABS (Acrylonitrile Butadiene Styrene) Pipes

-

PVDF (Polyvinylidene Fluoride) Pipes

-

LLDPE (Linear Low-Density Polyethylene) Pipes

-

PB (Polybutylene) Pipes

1. PVC (Polyvinyl Chloride) Pipes

-

Materials: PVC pipe are manufactured through Polyvinyl chloride which is a synthetic plastic polymer. This material is produced from ethylene, which is gotten from natural gas or petroleum, and chlorine, which is gotten from salt. The polymerization process provides a strong, light weight material which is useful in fabricating rigid pipes used in plumbing and construction industries.

-

Properties: PVC pipes are easy to handle, sound like concrete, do not corrode, resist most chemicals and ultraviolet radiation. It has a glossy interior surface that does not allow for deposition and hence blocking. PVC pipes is also relatively cheap and does not even call for complex tools to be fitted or cut into the required shape.

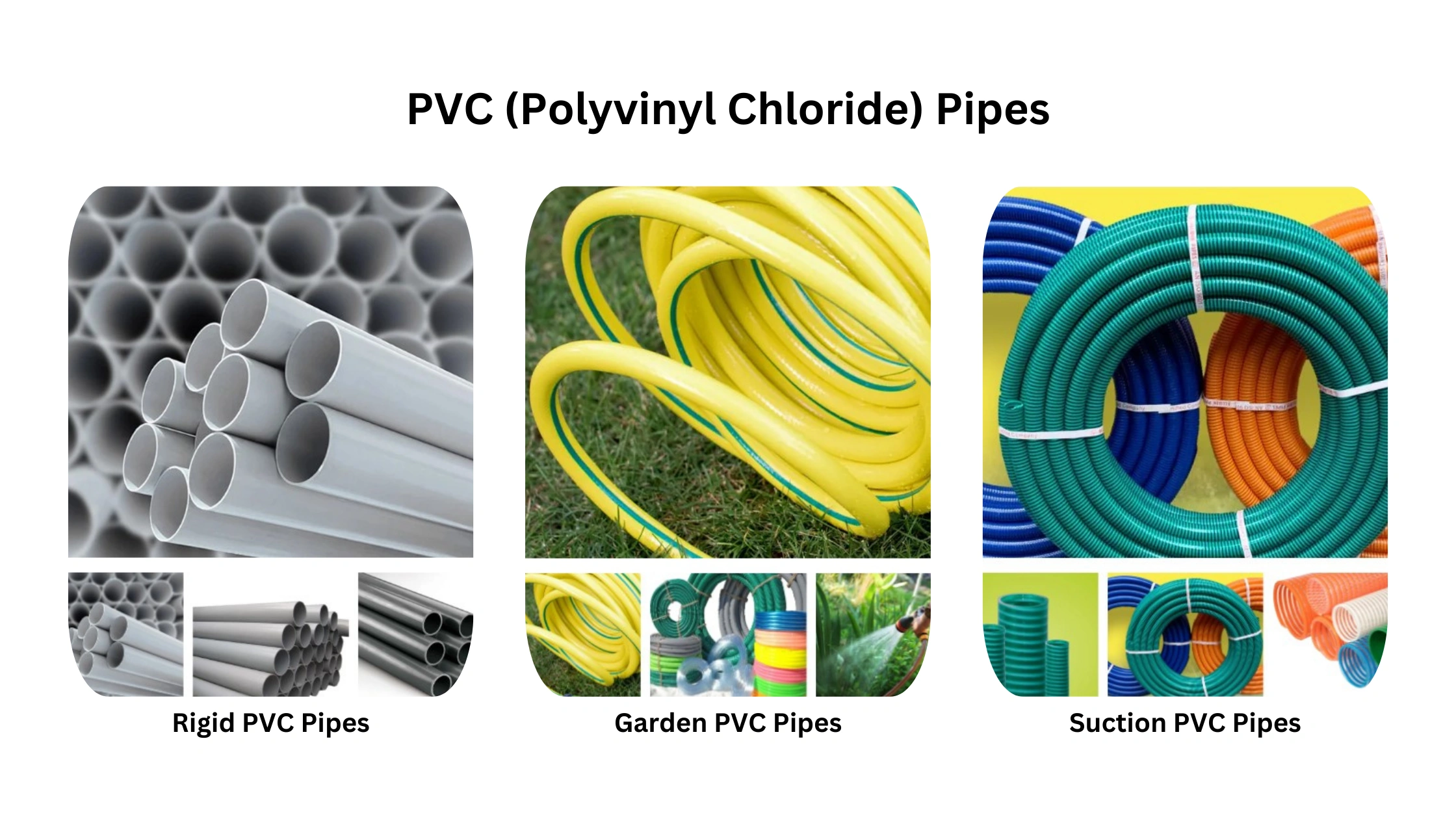

A. Rigid PVC Pipes: Durable and Reliable for Industrial Uses

-

Made From: Polyvinyl Chloride (PVC), which is a polymer of ethylene and chlorine and is processed to assume a rigid structure to fit the need for long lasting pipes.

-

Properties of Rigid PVC Pipes: Tensile strength, resistance to corrosion and fatigue, low density and ease of fabrication.

-

Uses in Various Industries: Water systems and sewage and waste disposal systems in residential and business establishments. Such as in the industries used for transportation of water and chemical;. Participation in construction, focus facilities, and drainages systems, water supplies.

B. Garden Pipes: Flexible and Essential for Outdoor Uses

-

Made From: Polyethylene or PVC, selected for their flexibility, stability, and appropriateness for acclimatized conditions, as well as their capacity to resist external pressures and external impacts in the cases of installations outside buildings.

-

Properties of Garden Pipes: Durability and elasticity as well as wear and abrasion resistant surface and insensitivity to changing weather conditions.

-

Uses in Various Industries: Highly applicable in the planting and management of homes out layout as well as landscaping sectors. Contributions of the four structures to agriculture for purposes of irrigation. Cleaning, rinsing, and draining for home environment purposes.

C. Suction Pipes: Essential for Fluid Movement

-

Made From: Polyvinyl Chloride (PVC) or Polyethylene (PE) since these materials are very chemically resistant, flexible and strong for conveying different fluids.

-

Properties of Suction Pipes: Chemical resistance and ability to cope with rugged conditions.

-

Uses in Various Industries: Water injection pumps and fluid movement in irrigation and other process industries. Sewage treatment, waste disposal and recycling, water purification and water management. Conveying slurries and liquid in mining and construction sectors.

2. UPVC (Unplasticized Polyvinyl Chloride) Pipes

-

Materials: UPVC stands for unplasticized polyvinyl chloride that is characterized by relatively high level of PVC rigidness that does not incorporate plasticizers. Lack of plasticizers as additives imparts increased strength and dimensional stability to UPVC making it immune to UV radiation and chemical research and weathering. UPVC pipes are used in cold water supply, drainages or to transport fluids in industrial concerns.

-

Properties: UPVC pipes have some physical and chemical properties such as rigidity, mechanical strength, weather resistance, resistance to chemicals and UV degradation. They are tough and relatively light and their interior surface offers minimal contact friction. For this reason UPVC pipes is free from any kind of plasticizers and are comparatively stronger and rigid than PVC.

3. CPVC (Chlorinated Polyvinyl Chloride) Pipes

-

Materials: As it is, CPVC pipes are produced by chlorinating polyvinyl chloride or PVC. This chlorination process elevates the chlorine on the base PVC polymer making the material to have the capability of withstanding high heat and also chemically stable. Therefore, the quality of the CPVC pipes is better than regular PVC pipes especially in temperature areas such as hot water and industrial fluids use.

-

Properties: Due to the incorporation of the chlorine molecules, the pipes made from CPVC are preferred than those from PVC. This makes them capable of operating at a temperature of up to 2000 Fahrenheit (93 Celsius). These are long-lasting, anti-corrosive, and immune to several chemicals meaning they can be used in several applications of a plumbing system.

4. HDPE (High-Density Polyethylene) Pipes

-

Materials: High density Polyethylene or HDPE Pipes are manufactured from high density polyethylene which is a thermoplastic and is obtained from petroleum. This material has a complex molecular structure and can therefore easily handle tension and is flexible at the same time. The inherent properties of HDPE gained from the polymerization process include non-corrosiveness, non-degradability by UV and resistance to environmental stress, which makes the pipe suitable for underground or high pressure pipelines.

-

Properties: HDPE pipes have relatively high values of strength and flexibility, low erecting costs, and fire resistance, impacts and chemical resistance, as well as environmental stress. It has many years of service and possesses high anticorrosive features, which make it suitable for underground use. The inner surface is polished so as to reduce the friction between its walls and the more efficient flow of the contents.

5. PEX (Cross-Linked Polyethylene) Pipes

-

Materials: PEX pipes are of polyethylene, which is defined as a polymer of ethylene. The polyethylene is treated with heat, chemicals or radiation during the production so as to enhance the properties of heat, strength as well as elasticity. Crosslinking enhances the performance capabilities of PEX by making it able to stretch and compress whenever temperatures fluctuate without requiring conversion into one solid piece.

-

Properties: PEX pipes are quite versatile and resist high temperature and corrosion. Cross-linking makes them stronger and more resistant and enables them to swell and contract without material deterioration. They are also immune to scale formation and chlorine making them suitable for use in those plumbing systems.

6. PP (Polypropylene) Pipes

-

Materials: Pipes and fittings are available in PP which stands for polypropylene this is a thermoplastic created through the polymerization of the monomer propylene. Polypropylene is a polymer that provides chemical inertness, high heat-resistance and also good mechanical properties. These characteristics qualify PP pipes for high temperature and chemical transport uses.

-

Properties: Polypropylene pipes are chemical proof, strong and light in weight. They are characterized by high melting points and hence one of the best options for application in high temperatures. PP pipes are also resistant to fatigue and stress cracking, it is also found to has longer service life than those of other plastic pipes.

7. ABS (Acrylonitrile Butadiene Styrene) Pipes

-

Materials: It is essentially a plastic pipe manufactured from ABS, a copolymer, formed by the combining of three monomers, namely acrylonitrile-b-butadiene-styrene. This alloying offers comfort in terms of strength, durability and resistance to chemical erosion. ABS PVC material has high strength, high rigidity and high impact, and high physical and chemical stability; it can be widely used in drainage and waste systems.

-

Properties: ABS pipes are fairly rigid, strong and highly capable of withstanding pressure from impacts besides having resistance on all chemicals in a given range. It has been identified that they have a low density and also offer relatively good protection against UV breakdown. In like manner, the interior surface of ABS pipes is smooth to avoid blockage and to allow for fast flow of water.

8. PVDF (Polyvinylidene Fluoride) Pipes

-

Materials: pvdf pipes, pipe, fittings are manufactured from polyvinylidene fluoride, popularly referred to as PVDF which is a highly non-reactive and durable thermoplastic. It is synthesized by the polymerization of vinylidene fluoride monomers These monomers are molecules from which individual polymer chains are derived. PVDF is acid and alkali resistant, UV protected and have high temperature withstanding capabilities which make it best suited for industries that deal with high purity fluids or movement of aggressive chemicals.

-

Properties: PVDF pipes possess excellent chemical resistance, UV stability and superior high temperature capability. They are strong, quite flexible, and possess high chemical and solvent resistant characteristics. These pipes can also support temperature up to 300°F (150°C) and also another advantage is that the pipes offer low coefficient of friction.

9. LLDPE (Linear Low-Density Polyethylene) Pipes

-

Materials: LDPE pipes are manufactured using linear low density polyethylene that is polyethylene formed from ethylene in particular with low density molecular arrangement. This structure produces flexible and tough material. LLDPE has higher strength and environmental stress crack resistance than low-density polyethylene (LDPE) and is used in water and drain applications at low pressure.

-

Properties: LLDPE pipes are thus flexible, light weight and more resistant to cracking than HDPE pipes. They are quite resistant to chemical attacks and mostly applied in low pressure applications. LLDPE is UV resistant as well as has good resistance to chemicals, oxygen, moisture, as well as ozone.

10. PB (Polybutylene) Pipes

-

Materials: PB pipes are made from a thermoplastic polymer called poly butylene which is gotten from butene. Butylene is a flexible material, chemically resistant and offers relatively good protection against scale formation. It is less permanent to UV degradation and chlorine than other plastics, and due to this, its use in plumbing has recently reduced.

-

Properties: Polybutylene pipes are flexible, very light and can be easily installed. It is known that they do not easily corrode or develop scale and have low heat transfer coefficient. However, they are not as strong as some of the other plastic pipes are particularly when exposed to chlorine or heat for long.

Innovative Pipes for Your Needs!

Roles of Plastic Pipes in Various Industries

Water Supply & Drainage System: PVC pipes are today used for water supply for both cold water and distribution of electricity and Telephone cables, drainage and sewerage system. They are suitable for use in homes, businesses, and firms, and industries where they will be exposed to chemicals with minimal wear and tear. PVC has also found wide application in irrigation systems and transportation of non-potable water due to its high vandal proof standard and ease of installation.

Construction and Plumbing: Plastic pipes are widely used in construction today especially in the housing segment and business undertakings in the delivery of water, for drainage and sewages. These are considered suitable for today’s plumbing requirements because they are light and do not corrode easily.

Agriculture: Polyvinyl chloride pipes are commonly employed in floods and irrigation thus guaranteeing a succeeding water supply in the fields. Owing to these properties they are ideal in any location that has direct contact with the harsh environmental factors.

Chemical and Industrial Applications: In businesses involving the transportation of dangerous products, plastic pipes are corrosion proof and safe. It is applied in the processing plants and laborites due to their stability in chemical reactions.

Oil and Gas: Plastic pipeline whose pressure is high is utilized in conveying of oil and the gasy. Actually, HDPE pipes are favored for their high carrying capacity and capacities to meet essential safety requirements.

Telecommunication and Electrical: In the telecommunication and electrical sector, cables are covered by plastic pipes. Due to their corrosion and environmental resisting capability, they promote sustainable water management systems.

Advantages of Plastic Pipes

-

Corrosion Resistance: In fact, plastic pipes cannot rust or corrode like the metal pipes; they surface is very smooth.

-

Lightweight and Easy Installation: In addition it is easier to transport and install plastic pipes, as compared to uses of traditional materials.

-

Longevity: They have a longer life span hence do not often need to be replaced as often as other sharply tipped products.

-

Versatility: Versatile to be used in different sectors of the economy.

Conclusion

There are good reasons why plastic pipes are flexible, effective and essential in many businesses. Recognition of the differences between various types of plastic pipes helps companies simplify the selection process depending on the necessities of a particular organization. And the more new technologies are developed the better perspectives will have an industry of plastic pipes.

We are dealing in Imported Rigid PVC Pipes, UPVC Pipes, Garden Pipes and Suction Pipes for houses, offices and other constructions. These principles make us your reliable contractor and supplier of all kinds of piping systems. Our products range of pipes and fittings are very useful for water supply as well as in agriculture for irrigation purposes and can fully satisfy the Organisation requirement in terms of its standard as well as its durability. Got Scotto Pipes for quality products for assured high performance.

FAQs

1. What are the most commonly used plastic pipes in plumbing?

PVC pipes are among the most popular choices for plumbing systems.

2. Are plastic pipes environmentally friendly?

Recyclable and eco-friendly plastic pipes are becoming increasingly available, addressing environmental concerns.

3. What factors should be considered when choosing a plastic pipe?

Key factors include temperature resistance, chemical compatibility, application requirements, and cost.

4. What is the difference between PVC and UPVC pipes?

UPVC pipes are more rigid and durable as they lack plasticizers, making them suitable for heavy-duty applications.

5. Are plastic pipes environmentally friendly?

Yes, many plastic pipes, such as UPVC and recycled PVC pipes, are environme