Introduction

Suction pipes constitute a very crucial component of numerous industries such as agriculture and construction up to chemical and water management. These pipes are designed to transport liquids, slurries or even light chemicals under suction pressure and are appreciated due to their durability, flexibility and affordability. The PVC suction hose pipes have gained popularity particularly due to their strength and handling capabilities among the various types.

But have you ever thought of the process of making suction pipes? In this blog, we will take you through step wise manufacturing process, framing materials, how various sizes: 2 inch, 3 inch and 4 inch suction pipes are made and how they are priced in the market.

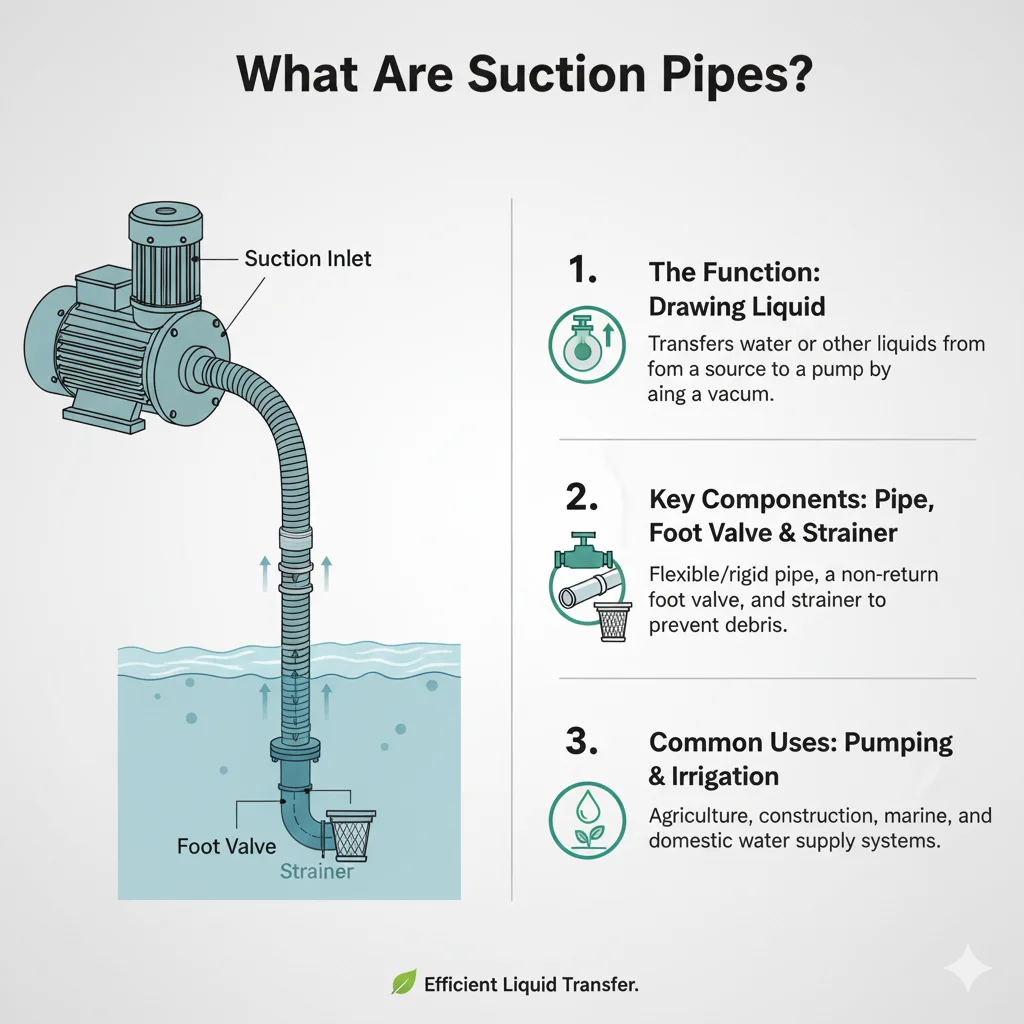

What Are Suction Pipes?

A suction pipe is a specially designed hose with a purpose to draw liquids and other substances by suction pressure. Suction pipes are reinforced unlike the regular pipes, which would collapse under negative pressure.

Some of the typical variations include;

-

PVC Suction Hose: light, strong and are employed many times in agriculture.

-

Flexible Suction Hose: is easily bendable and can be installed.

-

Suction Hose Pipe: comes in various dimensions that are used in various applications.

Suction pipes are important in their everyday use as they be it in irrigation in farms or dewatering in construction sites.

Raw Materials Used in Manufacturing

The raw materials are a big determinant of the performance of a suction pipe. As a rule, manufacturers employ:

-

PVC Resin: the strength and structural base.

-

Plasticizers: to be made pliable.

-

Stabilizers & Additives: to ensure that the pipe is strong to UV rays, heat and chemicals.

This combination makes sure that the suction pipes are strong yet they are lightweight and easy to carry around.

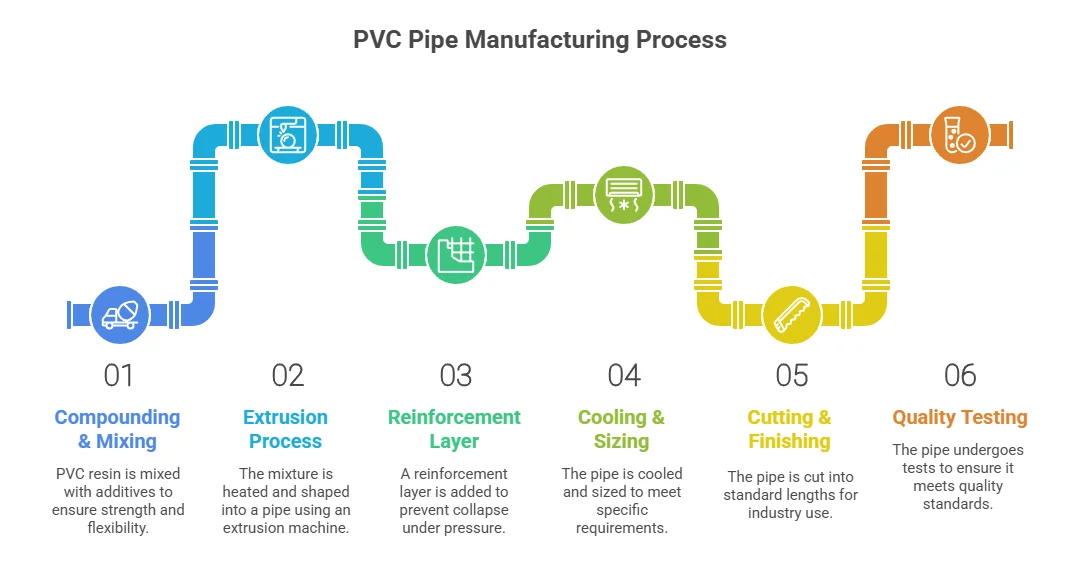

Step-by-Step Manufacturing Process

1. Compounding & Mixing

PVC resin is mixed with plasticizers and stabilizers among other additives and the process starts. This makes sure that the pipe has the appropriate strength, durability and flexibility.

2. Extrusion Process

The mixture is placed in an extrusion machine and heated. The PVC melts under high temperature and pressure, which is forced through a die to shape into a pipe shape.

3. Reinforcement Layer

To ensure extra reinforcement, most suction hoses are reinforced. This may be a spiral steel wire or polyester cloth built into the pipe wall that will not allow it to collapse due to suction pressure.

4. Cooling & Sizing

The hot pipe is cooled in water tanks after extrusion. This is the step which fixes the desired diameter and keeps it round. The pipe is also sized based on its use requirements which include 2 inch suction pipe, 3 inch suction pipe or 4 inch suction pipe.

5. Cutting & Finishing

The pipe is cut into standard lengths after being cooled normally to 30 -100 feet depending on the needs of the industry.

6. Quality Testing

Every batch is tested on pressure resistance, flexibility and chemical compatibility. This will guarantee that the suction pipe line will work in the real world.

Sizes and Pricing of Suction Pipes

The suction pipes come in various sizes and the prices differ according to the size and quality of the suction pipes. For example:

-

Suction pipe 2 inch: low cost, light weight, most frequently applied to small pumps.

-

Suction pipe 3 inch: mid-size, all purpose in agriculture and construction.

-

Suction pipe 4 inch: heavy duty, to be used with large-scale water transfer or industrial applications.

Market rates vary, but generally:

-

2 inch suction pipe price: budget-friendly for farmers.

-

3 inch suction pipe cost: Average, based on brand and life expectancy.

-

4 inch suction pipe price: higher due to more material and strength required.

In making a choice, always consider the cost and durability and application.

Applications of Pipe Solutions in Industrial Chemical Handling

Industrial chemical handling relies on the right pipe solutions to ensure safety and efficiency:

-

Water Treatment Plants: PVC, CPVC and HDPE water pipes carry chemicals such as chlorine innocently.

-

Petrochemical/refinery: Stainless steel and composite pipes are used when dealing with high pressure corrosive liquids.

-

Pharmaceuticals: PVDF, sanitary stainless steel are chemically pure.

-

Food & Beverage: PVC and stainless steel pipes avoid contamination of the chemical processes.

-

Industrial Processes: HDPE and flexible hoses facilitate the transportation of chemicals in a mobile or temporary way.

-

Storage & Distribution: Tanks and pipelines are linked through reinforced and stainless steel pipes which are safe.

Benefits of PVC Suction Hose Pipe

Why is the PVC suction pipe the most preferred option?

-

Lightweight: Easy to transport and install.

-

Flexible: This is in flexion so that it can bend without breaking in contrast, to the rigid pipes.

-

Strong: Strengthened with resistance to suction crushing.

-

Economical: Provides economy over rubber or steel equivalents.

FAQs About Suction Pipes

Q1. How are suction pipes manufactured?

They are made through extrusion, reinforced with spiral or fabric, cooled, cut, and tested for quality.

Q2. Which material is best for suction hose pipes?

PVC is the most widely used due to its strength, affordability, and flexibility.

Q3. What is the difference between PVC suction hose and rubber suction pipe?

PVC suction hoses are lighter, cheaper, and resistant to corrosion, while rubber hoses are heavier but offer higher temperature resistance.

Q4. How do I choose the right suction pipe size?

It depends on your pump capacity and application. Smaller pumps usually need 2 inch suction pipes, while larger ones require 3 inch or 4 inch suction pipes.

Choose the Right Suction Pipe!

Conclusion

Suction pipes may look simple, but their manufacturing involves a precise process of mixing, extrusion, reinforcement, cooling, and testing. Available in sizes ranging from 2 inch to 4 inch, these pipes are vital for industries that require efficient fluid transfer.

If you’re planning to buy, always compare the suction pipe price along with durability and application suitability. A well-chosen suction hose pipe can save both time and money in the long run.

At Scotto Pipes, we take pride in being a trusted manufacturer of PVC pipes, UPVC pipes, suction pipes, and garden pipes, offering products designed to meet both domestic and industrial needs. Our commitment to innovation, precision engineering, and reliability ensures that every pipe we produce delivers long-lasting performance. Whether you need piping solutions for agriculture, construction, or everyday use, Scotto Pipes is your dependable partner for quality and strength